Range of functions and possibilities

With the Monitoring System, Grindaix offers its customers a comprehensive system for the digitalisation and monitoring (Condition Monitoring) of processes and plants. The components of hardware and software offer a high flexibility and at the same time easy operation. It is designed for any industrial process and is not bound to any manufacturer of sensors, plants or machines.

In your personally adapted dashboard, the measurement data are assigned to the individual processes and displayed in a structured way. Based on the current and historical data, trends or deviations can be detected by you at an early stage and optimization potentials can be derived.

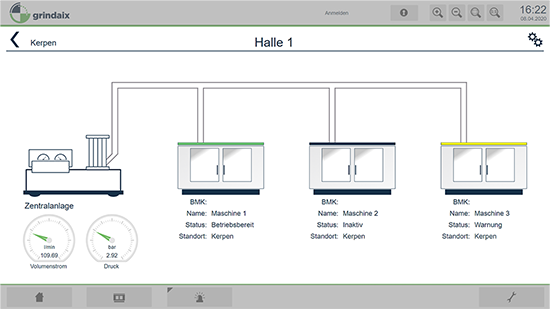

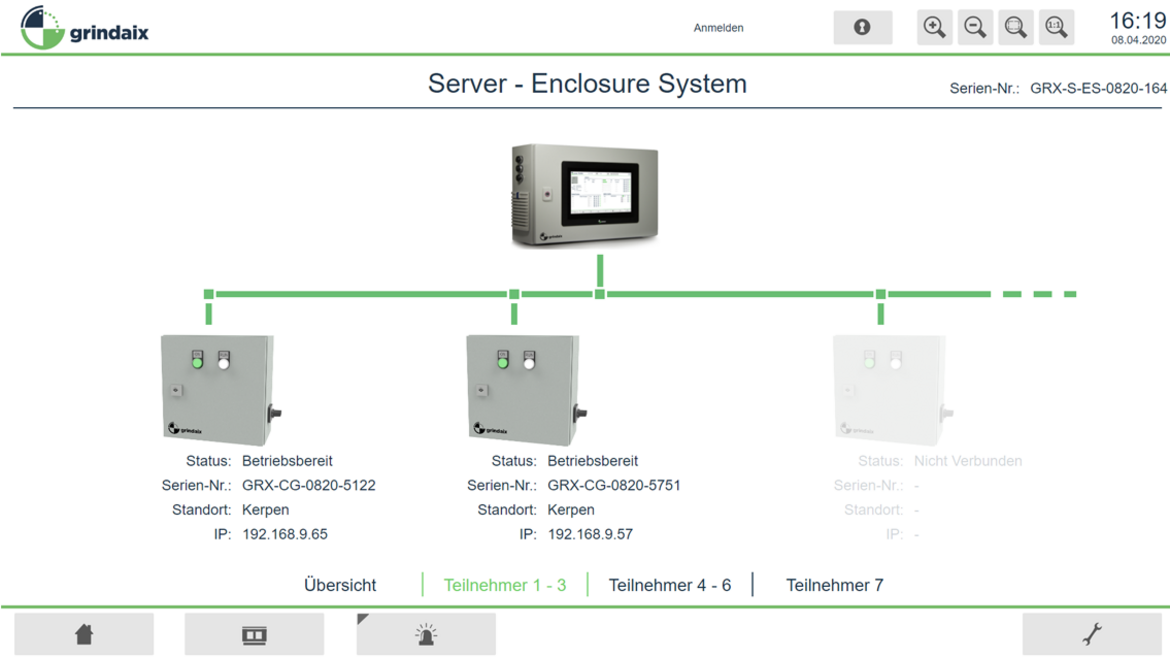

Monitoring Software

The Grindaix Monitoring software package in combination with the Grindaix hardware provides the foundation for digitising processes. While data acquisition is realized by the Grindaix hardware, the software provides the functions data storage, data display and process monitoring. To visualize the data, the device- and operating system-independent dashboard is called up via Web Client (browser).

Real-time monitoring

In the dashboard, the measurement data is assigned to the individual processes and thus displayed in a structured way in one place. Based on the current and historical data, trends or deviations can be detected by the customer at an early stage and optimization potentials can be derived.

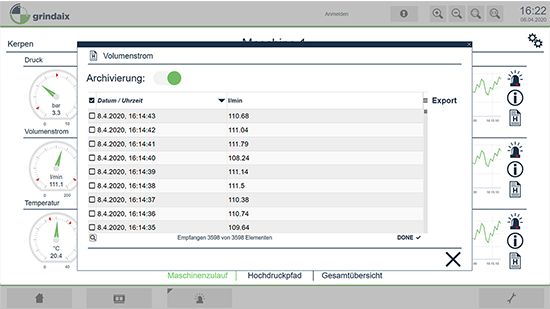

Data History

The data recorded by the hardware is stored in a SQL-Light database with time stamp. The archive data can either be accessed directly in the dashboard or read out of the SQL-Light database by an external access.

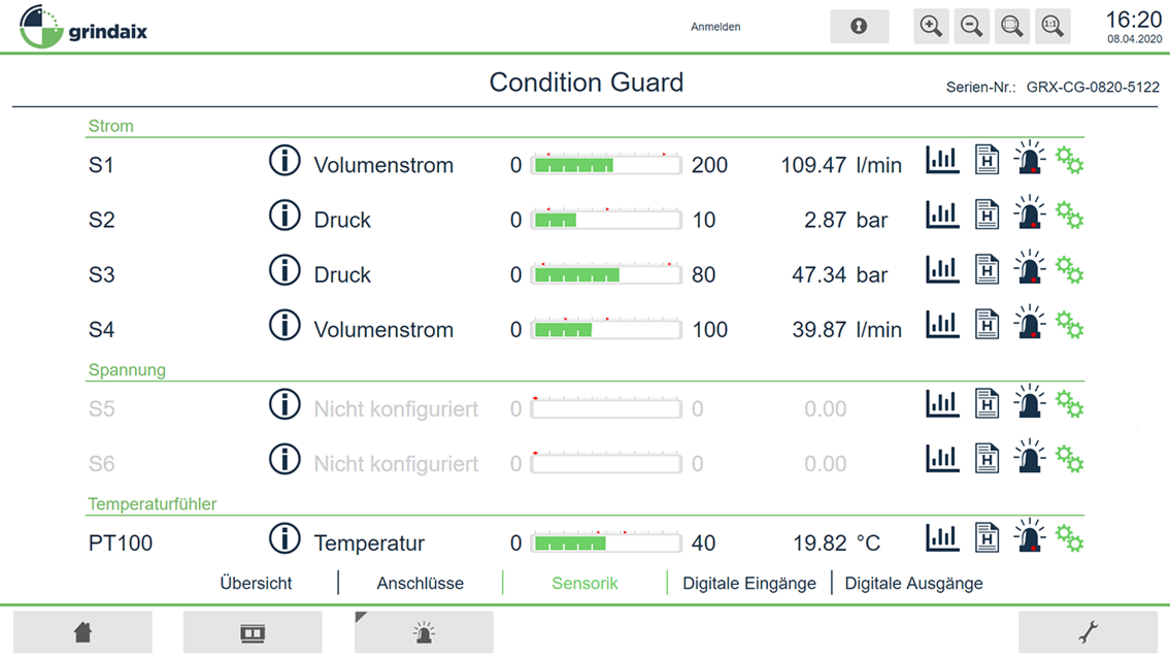

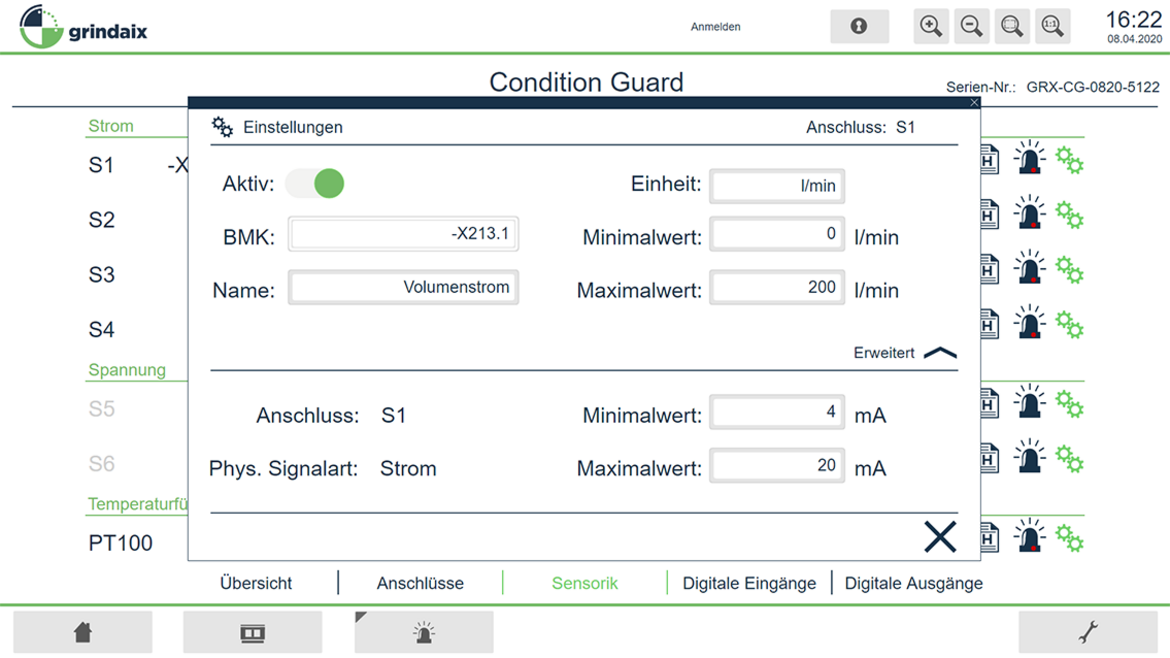

Limit value dependent monitoring

In addition to the clear data display, limit values for warnings and alarms can be set via the dashboard. Via digital inputs of the Grindaix hardware different process states can be recorded and the limit values for each sensor/measured value and for each process state can be defined individually. A return of a limit value violation can be made via the digital outputs of the hardware e.g. to a signal light or the control of the monitored process. This allows automatic monitoring with low latency. This offers the possibility to perform a fast data analysis, to proactively derive measures and to avoid errors.

Your opportunities

Authorizations can be assigned by a user administration with different access levels. Access rights can be distributed from pure data display for selected processes to the definition of limit values and the configuration of the sensor technology of the entire system. Thus the system can be adapted to the individual requirements of the users. Critical data is protected against unwanted access and settings can only be made by qualified personnel. The user administration thus offers a high degree of security against unwanted changes to the system and a clearly defined flow of information.

Your advantages

- Device independent access via standard web browser

- Data transmission based on OPC UA

- Sensor manufacturer neutral signal processing

- Alarm management

- Online and offline signal trends

- Historization of the measurement data in a SQL-Light database

- User administration with different access levels

- Simple configuration of the monitoring system