Page 48 - Grindaix-product-catalogue-english

P. 48

MEASUREMENT AND CONTROL SYSTEMS MEASUREMENT AND CONTROL SYSTEMS

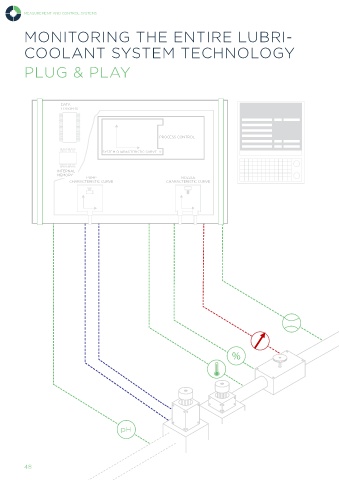

MONITORING THE ENTIRE LUBRI-

COOLANT SYSTEM TECHNOLOGY

PLUG & PLAY

DATA

DATEN-

LOGGER

LOGGERS

PROCESS CONTROL

PROZESSREGELUNG

SYSTEMKENNLINIE

SYSTEM CHARACTERISTIC CURVE

INTERNER

INTERNAL

MEMORY

SPEICHER

PUMP NOZZLE

CHARACTERISTIC CURVE CHARACTERISTIC CURVE

PUMPENKENNLINIE

DÜSENKENNLINIE

%

We are contributing to Industry 4.0 by providing process data relating to lubricoolants. Our Grindaix monitoring

systems check the relevant nozzle-related lubricoolant volume flow, the lubricoolant pressure at the Grindaix

nozzle and the lubricoolant exit speed. In addition, they also offer the possibility of transmitting the consumption

data of the relevant lubricoolant pumps, the percentage of CO emissions of the lubricoolant supply, as well as

2

other lubricoolant data such as temperature, pH value, etc. The data can be transmitted in real time and also as a

log of value over time. This enables you to monitor relevant lubricoolant system data, including error messages,

to ensure a robust manufacturing process as well as to track the component-related lubricoolant supply history.

pH

48 49