Page 6 - Grindaix-product-catalogue-english

P. 6

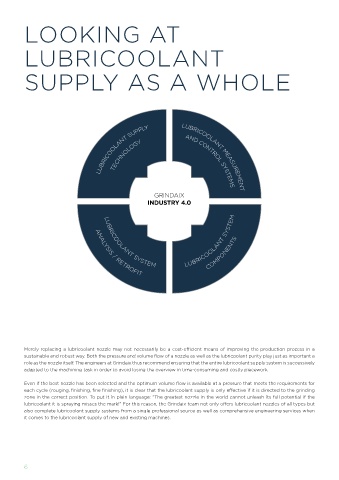

LOOKING AT In order to optimise the entire lubricool-

ant supply system, the following aspects

LUBRICOOLANT need to be taken in account:

SUPPLY AS A WHOLE

LUBRICOOLANT SUPPLY SYSTEMS LUBRICOOLANT SUPPLY COMPONENTS

Lubricoolant nozzles for technologies such as

Mechanical aids such as - lubricoolant filtration technology

- air spoilers - pressure control technology (constant

- nozzle wear protection systems pressure, cycle-adaptive)

- nozzle cleaning systems based on

compressed air

LUBRICOOLANT MEASUREMENT AND CONTROL SYSTEMS LUBRICOOLANT SYSTEM ANALYSIS / RETROFIT

A requirements-based 24/7 real-time lubricoolant A complete on-site technical analysis (Coolant Audit®)

monitoring and measurement technology for the with regard to:

digitalisation of process-relevant lubricoolant data on all - the pump design

your production machines. This data includes - lubricoolant piping systems and the professional

- pressures dimensioning thereof

- volume flows - pressure control technology (valves, controls

TECHNOLOGY AND CONTROL SYSTEMS

LUBRICOOLANT SUPPLY LUBRICOOLANT MEASUREMENT

GRINDAIX - temperatures - and lubricoolant filtration services

INDUSTRY 4.0 - lubricoolant purity

In the case of emulsions, chemical variables also need to

be considered. These include

LUBRICOOLANT SYSTEM LUBRICOOLANT SYSTEM

- pH value

- concentration

- conductance

ANALYSIS / RETROFIT COMPONENTS

- as well as bacterial attack (CFU)

Electronic operating aids such as

- laser positioning systems

- mobile display devices for visualization

“We do not fight symptoms, but

rather we eliminate the cause of your

productivity losses originating from

the lubricoolant supply sytem!”

Merely replacing a lubricoolant nozzle may not necessarily be a cost-efficient means of improving the production process in a

sustainable and robust way. Both the pressure and volume flow of a nozzle as well as the lubricoolant purity play just as important a

role as the nozzle itself. The engineers at Grindaix thus recommend ensuring that the entire lubricoolant supply system is successively

adapted to the machining task in order to avoid losing the overview in time-consuming and costly piecework.

Thanks to our 15 years of experience on more than 20,000 optimised machine tools, we have mastered the complex interaction of

Even if the best nozzle has been selected and the optimum volume flow is available at a pressure that meets the requirements for the numerous influencing factors to ensure successful lubricoolant supply technology. When optimising the lubricoolant supply, our

each cycle (rouging, finishing, fine finishing), it is clear that the lubricoolant supply is only effective if it is directed to the grinding additional know-how in production engineering and material sciences also enables us to identify problems in other areas that have

zone in the correct position. To put it in plain language: “The greatest nozzle in the world cannot unleash its full potential if the an effect on the overheating of components (e.g. component material composition, dressing, tool selection, process control, etc.) in

lubricoolant it is spraying misses the mark!” For this reason, the Grindaix team not only offers lubricoolant nozzles of all types but all production areas and thus to improve the process in an integrated and sustainable way in close cooperation with the customer.

also complete lubricoolant supply systems from a single professional source as well as comprehensive engineering services when

it comes to the lubricoolant supply of new and existing machines. Place your trust in the comprehensive optimisation capabilities of Team Grindaix!

6 7