Page 87 - Grindaix-product-catalogue-english

P. 87

LUBRICOOLANT SYSTEM COMPONENTS LUBRICOOLANT SYSTEM COMPONENTS

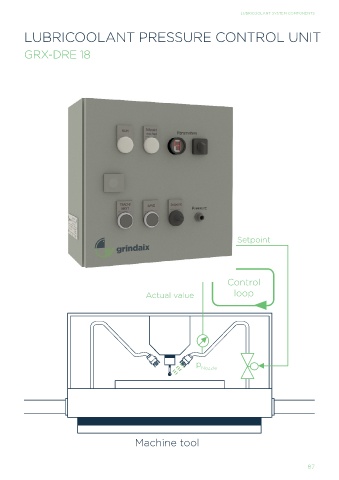

LUBRICOOLANT LUBRICOOLANT PRESSURE CONTROL UNIT

PRESSURE CONTROL GRX-DRE 18

RETROFIT KIT FOR EXISTING MACHINES

“The ability to easily adjust the

lubricoolant pressure

in front of the machine.”

With the aid of a pressure control valve, the pressure in front of the machine is regulated to a consistent value independent of the volume flow

requested. The pressure can be adjusted individually to the requirements of the machine or the nozzle (process/cutting speeds, etc.).

The pressure control valve ensures consistent conditions and reproducible processes on the machines. In addition, the lubricoolant supply to the

machines can be adjusted individually to the relevant processes, and lubricoolant can also be saved.

The Grindaix lubricoolant pressure control system takes on the entire pressure control task for you. The system uses a freely programmable parameter

memory for the pressure control target value. This parameter memory can be filled independently by you via an easy-to-operate teach function and

offers space for a total of nine lubricoolant pressure supply scenarios. We would be happy to accompany you through this during on-site system

start-up. The pressure control valve may also be opened completely. The parameter “0” is already reserved for this.

Stellwert

The pressure parameters can easily be changed manually via a selector switch. Optionally, the changes can be carried out externally via the machine Setpoint

tool. Simply contact us!

The lubricoolant pressure control system shows you the current operating status (control active / target value reached) via two indicator lamps.

In addition, the current pressure measurement can be easily viewed on the separately available Coolant Display. This is simply plugged into the

appropriate connector on the front of the pressure control unit. If the pressure sensor is linked to a nozzle, the Coolant Display also shows the

associated lubricoolant exit speed and the volume flow. Control

Regelkreis

Actual value loop

Istwert

ADVANTAGES

High-precision and continuously variable Lubricoolant supply savings

lubricoolant pressure control for all machine tools p

p

Incl. lubricoolant valve technology DÜSE

Nozzle

Compensation of pressure fluctuations and pressure surges and pressure sensorr for self-assembly

Robust processes due to consistent lubricoolant conditions

Machine tool

Werkzeugmaschine

86 87