Page 96 - Grindaix-product-catalogue-english

P. 96

GRINDAIX SERVICES GRINDAIX SERVICES

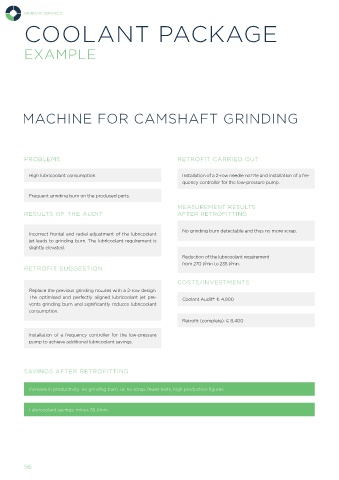

COOLANT PACKAGE

EXAMPLE

MACHINE FOR CAMSHAFT GRINDING

PROBLEMS RETROFIT CARRIED OUT

High lubricoolant consumption. Installation of a 2-row needle nozzle and installation of a fre-

quency controller for the low-pressure pump.

Frequent grinding burn on the produced parts.

MEASUREMENT RESULTS

RESULTS OF THE AUDIT AFTER RETROFITTING

No grinding burn detectable and thus no more scrap.

Incorrect frontal and radial adjustment of the lubricoolant

jet leads to grinding burn. The lubricoolant requirement is

slightly elevated.

Reduction of the lubricoolant requirement

from 270 l/min to 235 l/min.

RETROFIT SUGGESTION

COSTS/INVESTMENTS

Replace the previous grinding nozzles with a 2-row design.

The optimised and perfectly aligned lubricoolant jet pre- Coolant Audit®: € 4,900

vents grinding burn and significantly reduces lubricoolant

consumption.

Retrofit (complete): € 8,400

Installation of a frequency controller for the low-pressure

pump to achieve additional lubricoolant savings.

SAVINGS AFTER RETROFITTING

Increase in productivity: no grinding burn, i.e. no scrap, fewer tests, high production figures.

Lubricoolant savings: minus 35 l/min.

96 97