Zero grinding burn for higher productivity – Our Coolant Audit shows you how

Does grinding burn occur on your grinding machine during a productivity increase?

Is your tool life too short? Are your cycle times too long?

Has your lubricoolant supply reached its limits?

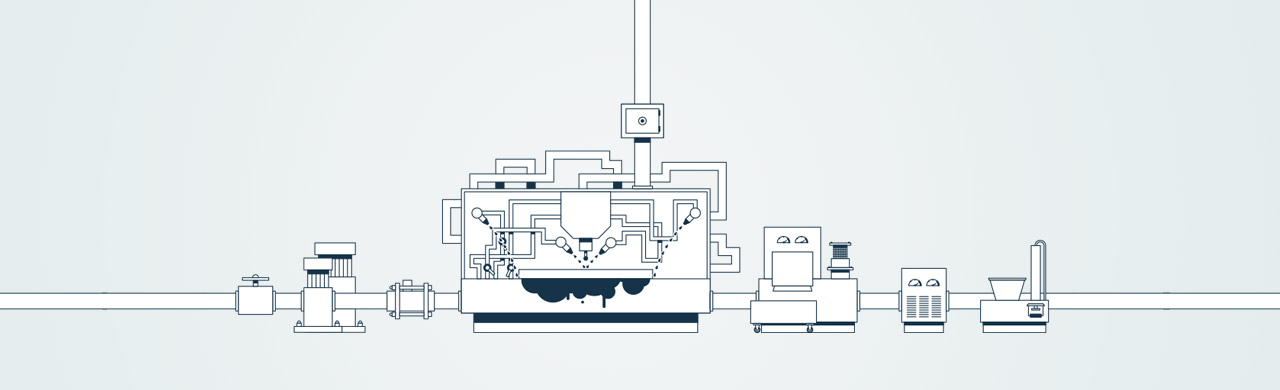

That doesn’t have to be! When it comes to such problems, Grindaix GmbH can assist you as a competent and experienced service provider. We analyse and assess your CNC grinding machine(s) as part of a “Coolant Audit”, which focuses on lubricoolant supply. We then generate a catalogue of concrete measures for increasing your productivity. In so doing, we not only consider the grinding machine but also all connected lubricoolant components – and always with your machining task in mind.

On-site analysis of the grinding machine

Our Coolant Audit encompasses a complete on-site analysis of your machine tool conducted by our lubricoolant specialists. The aim of this is to achieve process optimization of your machining task. During a Coolant Audit, we analyse all relevant lubricoolant data on your CNC grinding machine. This includes supply and return conditions on your grinding machine, part properties, the grinding wheel, the lubricoolant nozzles and the required lubricoolant volumes. We carry out these analyses primarily during running operation – the machine tool is only out of operation for approx. one hour.

Analysis of your grinding machine

Of course, merely surveying the lubricoolant parameters on your CNC grinding machine is not the only key to higher productivity during grinding or to eliminating grinding burn. The multitude of process parameters mean that there are many options for increasing productivity, which we can identify and assess using the acquired data. For this reason, we use the data obtained from your grinding machine to carry out a comprehensive evaluation following the on-site analysis. We compare all relevant lubricoolant system parameters and determine the optimum lubricoolant supply conditions for your CNC grinding machine.

Overview of our Coolant Audits

Our Coolant Audits for machine tools are based on your requirements and the specific problems and questions that arise in your individual machining task. Our audits for machine tools (Coolant Audit M) are subdivided into the audits M1/2 to M5 and cover all aspects that need to be examined from the existing machine to the new planning of a machine tool or production line. The scope of the individual audits for machine tools is clearly presented in the following table:

Audit type | ||||

|---|---|---|---|---|

Machine |

|

| ||

For users | ✓ | ✓ | ||

For machine manufacturers | ✓ | ✓ | ||

Goals | ||||

Avoid grinding burn | ✓ | ✓ | ✓ | |

Increase productivity | ✓ | ✓ | ✓ | |

Reduce coolant consumption | ✓ | ✓ | ✓ | |

Determination of the cooling lubricant requirement | ✓ | ✓ | ||

Increase energy efficiency | ✓ | ✓ | ✓ | ✓ |

Complete cooling lubricant engineering | ✓ | |||

Aftersales customer service with retrofitting | ✓ | |||

Service recipient - grinding burn | ✓ | |||

On site analysis | ||||

Pump technology | ✓ | ✓ | ||

Cooling lubricant supply | ✓ | ✓ | ||

Cooling lubricant system internals (valves, taps, pipes) | ✓ | ✓ | ||

Cooling lubricant consumption/ demand per grinding cycle | ✓ | ✓ | ||

Creation of a cooling lubricant consumption profile | ✓ | ✓ | ✓ | |

Preparation of a cooling lubricant pressure and quantity supply plan for individual and central supply | ✓ | ✓ | ||

Cooling lubricant coolant requirements in different operating scenarios, e.g. all machines in use | ✓ | |||

Redesign of all cooling lubricant nozzles, design of cooling lubricant pressures, flow rates, supply lines and components, pump type and performance taking into account the complete application spectrum of your machine | ✓ | |||

Creation of a cooling lubricant and electricity consumption profile: Pumps (kWh) and coolant (pressure/quantity) per cycle. | ✓ | |||

Results | ||||

Complete retrofit engineering (incl. drawings, technical data and product recommendations for optimum coolant supply) | ✓ | ✓ | ||

Cooling lubricant requirement plan for the ACTUAL state: preparation of an individual quotation for a Grindaix conversion package (nozzles, pumps, optimized settings) | ✓ | ✓ | ||

complete concept and design of the TARGET cooling lubricant situation incl. parts list, design drawings, detailed quotations | ✓ | |||

Advantages | ||||

Longer tool life | ✓ | ✓ | ✓ | |

Higher infeed/feed | ✓ | ✓ | ✓ | |

Grinding burn prevention | ✓ | ✓ | ✓ | |

Reduction of cooling lubricant and energy consumption | ✓ | ✓ | ✓ | |

Reduction of the filtration load | ✓ | ✓ | ✓ | |

Determination of cooling lubricant pressures and flow rates in line with requirements | ✓ | ✓ | ||

Acquisition of dimensional variables for coolant components and filtrations | ✓ | ✓ | ||

Customized optimized coolant supply | ✓ | |||

All details | ||||

Audit type |

Catalogue of measures for the grinding machine

As soon as we have analysed your CNC grinding machine completely, you receive a Coolant Audit report from us. This report supplies you with a comprehensive overview of your optimization possibilities and the associated improvement potential. The Coolant Audit report contains a detailed list of all weak points or problem areas found on the lubricoolant side in your CNC grinding machine. From this, we supply you with a concrete catalogue of measures, including a parts list for machine optimization, e.g. for increasing productivity while at the same time reducing grinding burn, shortening cycle times, increasing tool life and relieving the entire lubricoolant peripheral equipment, such as your lubricoolant filtration system!

Our Coolant Audits

Solve problems caused by grinding burn or low productivity by means of our sound and detailed analysis. Exploit the complete performance capability of your CNC grinding machine and reduce costs caused by part rejects, elaborate inspections and lubricoolant waste. You will be surprised at how quickly our audit is amortised.

We would be pleased to answer any questions you may have: info@grindaix.de or +49 (0) 2273 / 95 373 0

Our Machine Tool Audits

Our Filtration Audits

Procedure for a Coolant Audit M

1 Visit to your production environment

Our technicians visit you with all the necessary measurement equipment. Within a very short space of time (approx. 3h/machine), the periphery inside the machine is recorded.

2 Measurement of flow rates

By means of state-of-the-art measurement technology, we check the current lubricoolant flow rate per line. Depending on the audit, we also monitor all scenarios of your production process.

3 Recording supply pipes and fixtures

All pipes are completely recorded – from the lubricoolant supply connection to all nozzle exits. All geometrical and type values are also logged.

4 Analysis and evaluation of waste

We demonstrate how machining sites may be supplied in a robust way to meet the highest productivity demands, and how all waste in secondary zones may be avoided.