You can read the article on Quaker Houghton's site here: https://investors.quakerhoughton.com/news-releases/news-release-details/quaker-houghton-enters-joint-venture-grindaix

“This partnership is an excellent strategic fit with broad application. We see several advantages for our customers investing in system automation and optimization trends evolving from Industry 4.0,” said Joe Berquist, SVP & Chief Strategy Officer for Quaker Houghton. “Grindaix’s advanced capabilities enable us to deliver on our promise to make our customers more competitive, as we combine advanced product chemistry with equipment solutions to deliver an optimal package for performance, cost, and quality. We call this powerful combination 'Fluid Intelligence'. Grindaix’s data based approach to coolant system operation has been growing steadily in the German market, and we see an opportunity to leverage their technology across our broader solutions portfolio.”

"We expect close cooperation with our strong and professional partner to successfully establish state-of-the-art digitization solutions in the field of operating supplies for production machines," says Dr.-Ing. Dirk Friedrich MBA, Managing Director of Grindaix GmbH. “The aim is to offer our joint customers in the manufacturing industry the most innovative cooling lubricant supply technology and associated monitoring solutions with AI-based optimization tools and to harmonize this with the most economical application of process fluids for our customers worldwide. The entire team grindaix is looking forward to mastering the upcoming challenges even more successfully than we have done in the past.”

About Quaker Houghton

Quaker Houghton is a global leader in industrial process fluids. With a presence around the world, including operations in over 25 countries, our customers include thousands of the world’s most advanced and specialized steel, aluminum, automotive, aerospace, offshore, can, mining, and metalworking companies. Our high-performing, innovative and sustainable solutions are backed by best-in-class technology, deep process knowledge and customized services. With approximately 4,200 employees, including chemists, engineers and industry experts, we partner with our customers to improve their operations so they can run even more efficiently, even more effectively, whatever comes next. Quaker Houghton is headquartered in Conshohocken, Pennsylvania, located near Philadelphia in the United States. Visit www.quakerhoughton.com to learn more.

About Grindaix

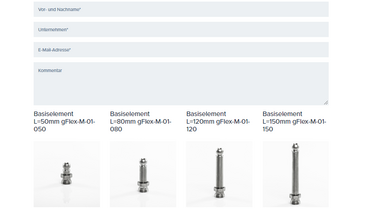

Grindaix specialises in optimising and modifying the lubricoolant supply systems for machine tools and in designing lubricoolant filtration systems that conform to technical, economic and environmental requirements. Or to put it simply: the technical solutions from grindaix let you avoid any waist of lubricoolant in your metal processing work. The young, innovative company, a spin-off from RWTH-Aachen, is dedicated to a solid yet very simple concept: a locally based, highly professional CRAFT solution to improve the productivity of manufacturing plants. Increased productivity and at the same time the avoidance of unnecessary demands on resources - that is our objective.