Filtration in the cooling lubricant circuit

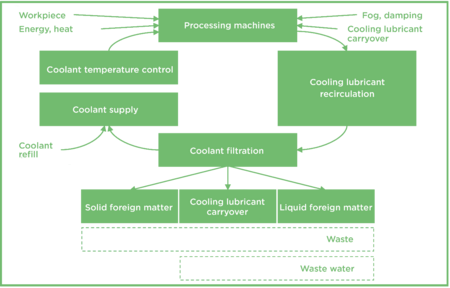

For economic and ecological reasons, cooling lubricants are fed into so-called coolant circuits. The structure of a coolant circuit is shown schematically in Figure 1. The purpose of coolant circuits is to ensure a constant supply of cooling lubricants to the machine tool and to continuously supply coolant of the required purity according to the requirements of the machine tool.

An important and central component of the coolant circuit is the coolant filtration unit. The main task of the coolant filtration unit is to filter or separate foreign particles from the cooling lubricant so that it retains as far as possible the properties of the delivered condition, especially with regard to purity. In the coolant circuit, coolant filtration follows coolant recirculation. Once the cooling lubricant has been freed of foreign substances in accordance with the required purity, it is available for the following circuit stages of coolant supply and coolant tempering.

Finally, it is returned to the machine tool and the cycle is repeated. During the cycle, cooling lubricant is inevitably lost. The main reason for this is the carryover of the coolant through the workpiece and the filtration unit.

Overview of material flows

Various material flows both enter and leave the filter system. The best way to illustrate this is by means of a diagram. Figure 2 provides such a diagram and thus makes it possible to illustrate the material flows that have a decisive influence on filtration.

Figure 2: Overview of material flows

During filtration, contaminated cooling lubricant, the so-called unfiltrate, flows into the filter. The unfiltrate is made up of the two material streams pure cooling lubricant, which is present in the coolant circuit before machining, and dirt, which results from machining. Furthermore, when a filter with precoating technology is used, precoating agent flows into the filter.

The precoating agent can be added continuously or precoated before the actual filtration. A combination of precoating and continuous dosing is common in practice. [Luc04, p.191 ff], [Gas00, p.48 ff].

The filtrate and the dirt cake leave the filter. The filtrate remains in the coolant circuit. The dirt cake, however, is removed from the coolant circuit. The filtrate is composed of the material flows of the remaining dirt, the cooling lubricant and the filter aid. Filter aid should not normally be present in the filtrate, but this cannot be ruled out due to the technical conditions. [Gas00, p.48 ff.]

The dirt cake is also made up of the three components dirt, cooling lubricant and filter aid. The dirt cake should have a high dirt content and the lowest possible coolant content.

The following relationships result from the conservation of mass for the "filter" system under consideration. The filter aid mass in the dirt cake adds up with the filter aid mass in the filtrate to the filter aid mass entering the filter.

The dirt mass entering the filter is divided into the dirt mass remaining in the filtrate and the dirt mass discharged with the dirt cake. The coolant mass entering the filter divides into the coolant mass of the filtrate and the coolant mass that is carried away with the dirt cake.

Technically reasonable structure of the filtration principles

Figure 3: Technically reasonable structure of the filtration principles

In the literature on general solid-liquid separation, there are different approaches to structuring the filtration processes. If one considers the filtration processes with regard to coolant filtration, Figure 3 provides a technically sensible and practice-related structure which allows the user a quick overview and orientation.

The filtration equipment practically used for coolant filtration can be divided into the four basic filtration principles:

- filtration by sedimentation

- filtration by centrifugal force

- filtration by size differences

- filtration by magnetic force action

Filtration by sedimentation

In filtration by sedimentation, the dirt is separated from the cooling lubricant by different sedimentation behavior. Due to the difference in density between the dirt and the cooling lubricant, the dirt settles on the bottom of the sedimentation unit and forms a sediment, which can finally be discharged as a moist heap. [VDI 3397]

Filtration by centrifugal force effect

In the case of filtration by centrifugal force, similar to filtration by sedimentation, the different densities of the cooling lubricant and dirt are used to achieve solid-liquid separation. In this principle, the cooling lubricant and dirt rotate on a circular path and the resulting centrifugal force effect concentrates the dirt, which has a higher density than the cooling lubricant, on the outer circular path and then discharges it.

Filtration due to size differences

Size difference filtration, also known as sieve filtration, makes use of the difference in size between dirt particles and coolant particles.

A filter medium, which in principle acts like a sieve, retains the dirt particles and allows the coolant particles to pass through.

Filtration by magnetic force action

Filtration by magnetic force separates dirt particles from the cooling lubricant which react to magnetic attraction. The dirt particles to be separated should be attracted by a magnet. In the optimum case, they are ferromagnetic and can become magnets themselves.

Sources

[VDI 3397]: Richtlinie VDI 3397, Pflege von Kühlschmierstoffen für die Metallbe- und –verarbeitung, 2005

[Luc04]: Luckert, K.: Handbuch der mechanischen Fest-Flüssig-Trennung, Essen, Vulkan, 2004

[Gas00]: Gasper, H.; Oechsle, D.; et al.: Handbuch der indust-riellen Fest/Flüssig-Filtration, 2. Auflage, Weinheim, Wiley-VCH, 2000

These articles from our magazine might also interest you:

Reduce CO2 emissions

Climate change, as described in a very detailed risk research by the European financial institutions, poses an unprecedented challenge to the governance of global socio-economic and also financially acting systems.

Advantages of Coolant Monitoring Systems

Coolant monitoring systems can significantly contribute to increasing reliability and efficiency by collecting and evaluating a wide range of measurement and condition data in the coolant system.

Zero Emission Production

Zero Emission Production helps to reduce carbon dioxide emissions permanently while at the same time increasing the availability of production resources and avoiding the waste of operating materials.

ROI-Digitization Projects

The digitization of production units offers a wide range of possibilities for networking existing machines and systems. In this article, we offer you a brief orientation in the subject matter.