AI - challenges

As already described in Chapter 3, the algorithms for the successful application of machine learning in production technology require as much good data as possible. Good data is data whose values are as correct as possible. This applies both to their mathematical value for describing a physical variable and to the temporally continuous correctness of the state of a particular datum, including whether it is still a relevant influencing variable on the defined target variable. Furthermore, the number of good data available is decisive. The more data of this data quality is available, the higher the subsequent functional quality of the “artificial intelligence” as the central control instrument of autonomous production.

This can be explained by the fact that the algorithms for learning a company-specific production behavior should have a good learning basis, similar to the learning process of a person. The higher the quality of its training, the higher its subsequent level of education. The quality of his training information (learning content) is a decisive factor in the quality of his skills later on. In a production environment, there are at least two relevant types of data families. On the one hand, there is the group of all technical sensor information, including that of product quality monitoring and the sensors installed in the production periphery, and on the other hand, there is the group of business information in the form of calculated data from existing software systems, such as ERP and accounting systems. The availability of these two data families (technology and business management) allows artificial intelligence to make the most accurate statements possible about the economic efficiency of the production environment under consideration. When selecting the data to be considered, care must be taken to maximize the amount of good data for training the mathematical model of the artificial intelligence.

Another factor is the time delay in the availability of information. For example, it is quite easy to provide a physical variable from the production environment in real time, but business values such as an operating result are often not available in real time due to possible booking delays. How does a mathematical model react to incomplete data sets? Or is a statistical probability calculated from the past in order to forecast the real time value of business data as accurately as possible? This means that there is a certain maximum tolerable uncertainty with regard to data quality for every optimization variable. What are the limits and relevance of such imprecision? Is there a sufficiently precise basis for evaluating forecasting models for key business data? In the context of autonomous production technology, it will therefore be useful to find out with what level of uncertainty in data quality an artificial intelligence optimization model still works with “sufficient” accuracy. The question of how the term “sufficient functional quality” of a mathematical model can be evaluated must be clarified.

There are various approaches to mathematical model validation, but these will not be explained in detail in this article. This means that there is also an economic optimum here in terms of providing data as well as necessary and not as well as possible.

Products relevant to this article:

You may also be interested in these articles from our magazine:

AI - opportunities

The opportunities that arise from the successful use of a production environment that is monitored in line with requirements and controlled by artificial intelligence are diverse and often unexpectedly full of potential.

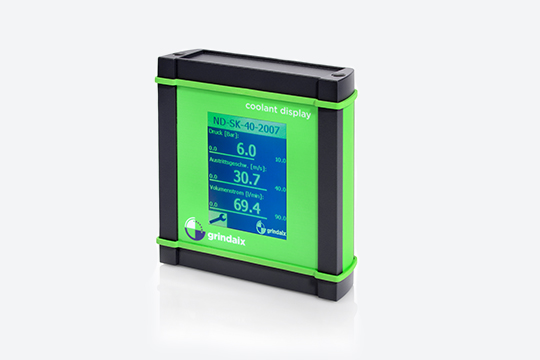

Cooling lubricant pressure control systems

Pressure control systems are particularly relevant for large and complex cooling lubricant supply systems. We have compiled the advantages over conventional pressure control systems and outline the technical implementation of an adequate pressure control system.

Frequent problems during grinding

Modern high-volume production facilities for metal components often have large and equally complex cooling lubricant systems. Keeping an eye on all parameters and ensuring reliable operation is therefore no trivial matter. Coolant monitoring systems can be used to support the monitoring of the cooling lubricant system.

AI - Risks

In addition to the many good opportunities and high potential benefits of artificial intelligence in production technology, there are also risks that need to be considered when implementing such capability tools.