GRX-Q - Volumetric measurement methods

The volumetric measuring method is based on the measurement of partial quantities of a medium to be measured. The medium passing through a defined measuring chamber or via an analog rotation of measuring vanes is added up. This summation is described by the term “transported quantity”.

Volume meters are divided into two superordinate groups, “direct volume meters” and “indirect volume meters”, depending on their mode of operation.

Indirect counters

With indirect meters, the volume is determined indirectly without a measuring chamber. There are various methods here. For example, the speed of the flow can be measured or the flow values can be integrated over a certain period of time. In this method, the density is usually an important variable to be taken into account, as this has an influence on the error curve of the flow meter.

Direct volume meters

In the direct methods, small volumes of the medium to be measured are delimited during the measuring process. The volumes are determined by the defined size of the measuring chamber or by the measuring chamber walls. The partial volumes passing through can be recorded and output with the aid of a counter. The direct volume meters are further divided into discharge and displacement meters.

Outlet meters consist of a measuring vessel with fixed measuring chamber walls. The medium to be measured is filled into the measuring vessel by a slight overpressure. The meter then empties automatically by means of tilting or control devices. The fluid flows out of the measuring chamber without pressure (see Fig. 2 4). This method is not suitable for measuring gases. This method can also be used to measure contaminated liquids, as the fluid always flows out through large drain openings or via tilting/rotating devices. The method can achieve accuracies of up to 0.1 %.

Displacement meters are characterized by movable measuring chamber walls that displace the medium to be measured. In contrast to outlet meters, this principle allows liquids and gases to be measured.

Due to the fact that outlet meters always delimit a certain volume, no continuous measurement can be carried out. In addition, the measuring containers are relatively large, which makes implementation in a cooling circuit unattractive. These outlet meters are therefore not suitable for the task at hand. For this reason, only individual displacement meters are discussed below.

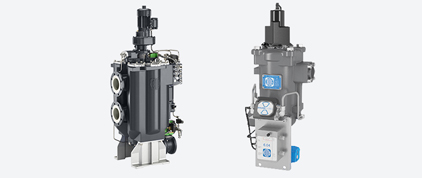

[Translate to Englisch:] In diesem Artikel relevante Produkte:

GRX-Q

You may also be interested in these articles from our magazine:

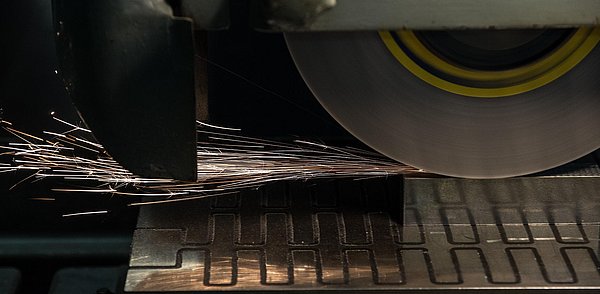

Frequent problems during grinding

Although grinding is a widely used manufacturing process, it is nevertheless complex and carries the risk of making mistakes in many places. In all cases, these have an impact on efficiency and component quality. Read on to find out what needs to be taken into account in detail and what the most common errors in grinding actually are.

Coolant filtration systems

Treatment is a crucial part of the cooling lubricant supply with a major impact on production results and efficiency. We have described and compared the usual filtration processes for cooling lubricants.

GRX-Q - Flow measurement

The flow measurement is part of the metrological determination of a volume flow Q or mass flow m=ρ∙Q. This is done as a function of a measuring cross-section A of a closed pipe or an open channel.

GRX-Q - Displacement meter

With the displacement meters, the moving measuring walls are driven by the medium to be measured. The movement is recorded and counted.