Grindaix nozzles as a special design

- Reduction of grinding burn risk

- Reduction in the cycle time / increase in productivity

- Longer tool life

- Adjustment and control of the lubricoolant exit speed

- Reduction of residues in the machining zone

- Lower lubricoolant requirement

Your nozzle specialists from the Grindaix team have longstanding experience and are thus highly familiar with the challenges presented by grinding. During more than 7000 machine optimizations, we have already successfully proven the benefits which our Grindaix nozzles bring.

As an experienced engineering service provider, we can plan, design and produce individual lubricoolant nozzles – developed to suit your production situation perfectly. Through this individual development and design we can offer you a whole range of benefits:

+Reduction of grinding burn risk

+Reduction in the cycle time / increase in productivity

+Longer tool life

+Adjustment and control of the lubricoolant exit speed

+Reduction of residues in the machining zone

+Lower lubricoolant requirement

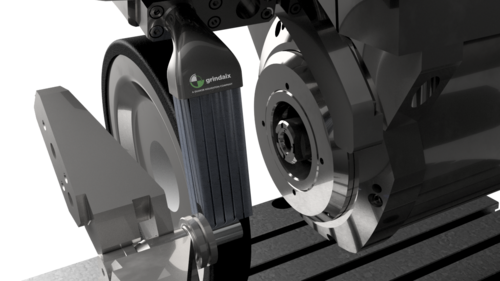

Our Grindaix needle nozzles are a particularly time-tested, established product. They enable precisely metered, targeted supply to the machining zone. To ensure that you can exploit all the advantages of our needle nozzles, we precisely adapt these to your CNC grinding machine and to your multiple-stage grinding process (roughing, finishing, fine finishing) – pressure-controlled with different lubricoolant supply scenarios. We also adapt the nozzles to the part to be produced for ensuring a collision-free process.

By generating or using a CAD-STEP file, we can consider all geometrical characteristics such as grinding wheels, interfaces to the machine nozzle holders, as well as the travel of your geometrically varied parts. This special engineering service is included in the nozzle price.

We supply all our Grindaix nozzles with a precise Grindaix nozzle characteristic curve. This provides you with exact information on which pressure is needed for obtaining which lubricoolant exit speed as well as how much volume flow is thereby required. This supports you in designing your pressure supply.

The precise coordination of all these important aspects promises an optimum machining result. Furthermore, your productivity increases and your production scrap rate decreases!

We supply all our Grindaix nozzles with a precise Grindaix nozzle characteristic curve. This provides you with exact information on which pressure is needed for obtaining which lubricoolant exit speed as well as how much volume flow is required. The characteristic curve thus supports you when designing your pressure supply.

This precise coordination promises an optimum machining result. Furthermore, your productivity increases and your production scrap rate decreases!

| Name | Type | Size | Download |

|---|---|---|---|

| Questionnaire for Nozzle Design | 494 KB | download |

Produktanfrage

Examples of special design nozzles in use

The special design nozzles from Grindaix GmbH are suitable for almost any grinding process, as they are individually designed for the process. This means that grinding processes such as turbine blade grinding, inter-point grinding or tool grinding are effectively protected against grinding burn.

Advantages in all grinding processes:

- Reduced lubricoolant consumption

- Optimum supply

- Reduction in grinding burn and tool wear

- Higher lubricoolant outlet speed

- Targeted cooling lubricant supply

- Increase in productivity

- Customized design, adapted to the process

- Benefits despite small installation space

Grinding of turbine blades

There are many different lubricoolant supply areas in the multi-cycle machining of turbine blades. The curved surfaces of turbine blades and the large number of parts that are difficult to access make the supply of cooling lubricant even more difficult. Grindaix nozzles specially adapted to the process can be used to supply sufficient lubricoolant to such hard-to-reach parts of the turbine blade and all areas of the grinding process. These nozzles ensure a targeted and adequate lubricoolant supply, while at the same time requiring less lubricoolant for cooling.

Intermediate point grinding

Intermediate point grinding is a form of cylindrical grinding where the workpiece is fixed between two centring points at both ends. However, the workpiece is not machined over its entire length due to a safety driver and the lubricoolant supply can also be made more difficult as a result. Furthermore, the inner edge can be problematic for an adequate supply of cooling lubricant due to the shape of the grinding wheel. The nozzles from Grindaix GmbH are individually adapted to the process and grinding wheel and thus ensure a sufficient supply of coolant even at hard-to-reach edges and zones. Together with the Coolant Protector as an air deflector plate, which keeps out disruptive air pockets, an efficient solution can be found for the process.

Tool grinding

Tool grinding involves machining tasks that are used to manufacture or overhaul a tool. Due to their areas of application, tools are often made of hard materials, which makes grinding more difficult and increases machining temperatures considerably. For this reason, a sufficient lubricoolant supply is essential. Complex component geometries, such as the grooves of a thread cutter and the associated changing contact areas, further increase the demands on the lubricoolant supply. Grindaix nozzles, individually adapted to your process, ensure a process-adapted cooling lubricant supply to all relevant, hard-to-reach zones that are at risk of grinding burns. At the same time, lubricoolant consumption is reduced.

Would you also like to optimize your grinding process with an individually adapted special design nozzle?

Equipment for the Grindaix special designs

The right equipment can significantly increase the durability and productivity of Grindaix special constructions. To make this possible, we have developed matching and coordinated accessories! The Coolant Protectors can be used to provide wear protection for almost all nozzle geometries. It serves as wear protection, air baffle and stabilizer. Furthermore, our coolant pressure gauges, as well as our Coolant Display and Coolant Pointer, have been developed for better and faster alignment and display of your coolant data. The quick-change systems, on the other hand, are used to exchange different nozzle variants and gFlex lengths quickly and practically.