AI - How do you proceed?

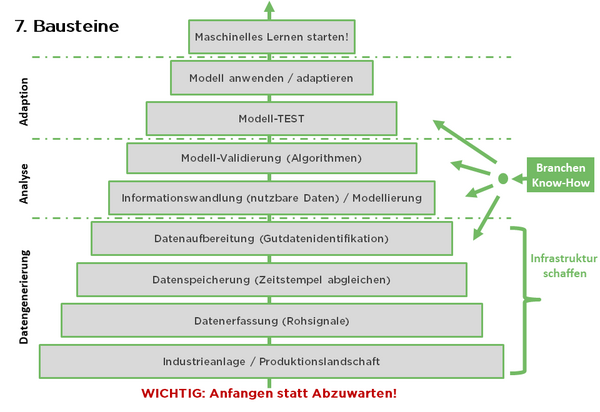

The first step in this context is to start implementation as soon as possible and not wait until a competitor has a solution. Because this solution, if it were available at all, certainly cannot simply be copied or purchased at the touch of a button. Rather, solutions for the implementation of autonomous production technology will have to be adapted to the specific characteristics of almost every production unit (location). This means that in the future, there will probably be no generally valid solution approaches of a specific algorithm for all production units, which may produce similar components with almost identical machines and automation systems. The use of artificially intelligent systems in the context of production technology will most likely remain a company-specific undertaking with many different learning curves, the use of a wide variety of algorithms and their mathematical adaptation to the specific application, with failures, successes and constant opportunities for improvement.

Determine optimization goals

Computer-controlled production requires specific optimization targets, otherwise the classic learning methods of artificial intelligence or machine learning cannot be applied. Such targets can relate to the number of good parts per hour or economic efficiency.

Priorities must be assigned. For example, the primary objective may be to reduce unit costs. Without the simultaneous target value specification of the number of pieces to be produced per time unit, the system may not work effectively.

One specific optimization goal is, of course, to maximize the number of good parts per hour in order to make production more effective and efficient. In this way, unit costs can be reduced.

Maximizing the number of good parts / hour = max {production output}

Profitability as a specific optimization target also contributes greatly to better production and lower unit costs.

Maximization of economic efficiency (€) = max {earnings per hour}

Data identification

The second step is to analyse what information (data) needs to be taken from the production unit in order to monitor and achieve this optimization goal. It will quickly become apparent that there can be an infinite amount. The trick is therefore to identify the most relevant information (in order of priority). Once relevant information has been identified, the question arises as to how this information is to be extracted from the production system. Not only the selection of a sustainably reliable sensor that is as accurate and low-maintenance as possible, but also its positioning within the production environment pose the first fundamental challenges. In the context of autonomous production, this is referred to as obtaining “good data”.

The mathematical model of “artificial intelligence” is only truly “intelligent”, in the sense of fulfilling previously defined optimization goals, if the information fed to it is sustainably correct and it can learn their interaction as error-free as possible. A correct datum is understood to mean not only its correct physical value, but also whether it is actually correct in the context of the optimization variable, that the respective information has a relevant influence on the optimization variable. The more qualitative the information fed to the system (good data) is, the more usable the statements (commands / recommendations) of the autonomous production control are, and the sooner an optimization maximum is achieved in relation to the clearly defined optimization targets.

Data acquisition

![[Translate to Englisch:] Datenerfassung mit KI [Translate to Englisch:] KI - Daten aus der Produktionsumgebung](https://grindaix.de/fileadmin/_processed_/f/7/csm_technology-5246655_1280_905524d5aa.jpg)

In a third step, the question arises as to how the data can be transferred from the production environment to a central IT control center with as little effort as possible. According to current industry norms and standards, the cable solution is the safest and most robust solution. Sensors are often not WLAN-capable, signal transmission can often be severely impaired by electromagnetic fields from the production equipment within the production environment, and the signals are often unencrypted and can therefore be intercepted by third parties (security).

It is therefore advisable to install the sensor signals on the production equipment via sophisticated and pre-programmed switch boxes with a unique IP address (origin of information) and then to transmit these signals very securely and digitally via a pre-configured bus system to a central point of use. There, the signals are initially recorded cleanly in parallel with a time stamp that is uniformly valid for the entire production unit.

Data storage

Such standard preconfigured data recording systems also provide the technically clean data storage function, including the necessary hardware and software. All recorded data is provided with a standardized time stamp. The exact identification of the data origin (IP address) assigns the information to a mechanical component (machine, pump, valve, unit, ...) and the time stamp provides the corresponding time assignment of a sensor value.

These two pieces of information are essential for the subsequent use of “artificial intelligence” in production technology. Without the precise assignment of the data origin and the exact time of the data value, the software-based intelligence to be installed later cannot logically link parallel events mathematically. The quality of this unambiguous data provision is therefore an essential component of the quality of successful production autonomy.

Once the data has been stored cleanly, including IP address (origin) and time stamp, this data must be made usable in such a way that it can be found easily if required (integrated search function) and used by further processing software programs (data formats). For security reasons, it should also be possible to carry out regular data back-up processes automatically. At best, the acquired unit of your data acquisition system can do this fully automatically.

Data analysis

Before feeding relevant data to the mathematical models (algorithms) of your AI (artificial intelligence) software, it is possible to exploit the full, previously unknown potential of such data utilization via practical monitoring functions. For example, users can easily program limit values for the recorded data via the central control unit included in the scope of delivery and thus very easily describe case events in order to achieve a monitoring function that meets the requirements. The central control unit visualizes limit value violations, outputs them in an error log and can report gross limit value violations (amount/duration) to a higher-level production control center or the monitored mechanical system (machine, pump, etc.).

As a successful consequence, this leads to the avoidance of reject production. If plausibilities, i.e. the simultaneous occurrence of different case events, are also programmed (if - then principle: e.g. if pressure p1 < pressure p2 - then message error 18), the system will already function successfully as part of a “predictive maintenance approach”. The advantage of this machine-independent data acquisition system lies primarily in the fact that it has an overview of the interaction of all monitored production equipment and can draw technical conclusions from this. The individual machine, however modern it may be, or the individual mechatronic production unit alone cannot do this. These individual components of the entire value chain are usually only able to optimize their own function, but not their optimal function in the context of the other means of production. A central data acquisition system in production technology therefore provides the possibility of technical communication between the installed production equipment in addition to the monitoring and predictive maintenance capability. This is the essential difference and at the same time the justification for the need for such a higher-level monitoring system.

Products relevant to this article:

GRX-Q

You may also be interested in these articles from our magazine:

AI - opportunities

The opportunities that arise from the successful use of a production environment that is monitored in line with requirements and controlled by artificial intelligence are diverse and often unexpectedly full of potential.

Cooling lubricant pressure control systems

Pressure control systems are particularly relevant for large and complex cooling lubricant supply systems. We have compiled the advantages over conventional pressure control systems and outline the technical implementation of an adequate pressure control system.

AI - challenges

As already described in Chapter 3 (AI - How to proceed), the algorithms for the successful application of machine learning in production technology require as much good data as possible. Good data is data whose values are generally as correct as possible.

AI - Autonomous production

Production technology is increasingly characterized by the use of computer-aided knowledge management systems. A distinction is made between expert systems that pursue a deductive learning approach and inductive optimization methods.