Page 65 - Grindaix-product-catalogue-english

P. 65

MEASUREMENT AND CONTROL SYSTEMS MEASUREMENT AND CONTROL SYSTEMS

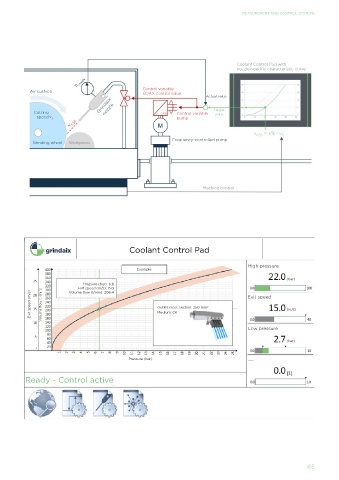

REGULATION AND CONTROL

COOLANT CONTROL SYSTEM

Coolant Control Pad with

nozzle-specific characteristic curve

p Nozzle

Air cushion Control variable Actual value

COAX control value

Grindaix

Cutting nozzle Control variable Target

value

speed pump

Frequency-controlled pump

Grinding wheel Workpiece

Machine control

COOLANT CONTROL PAD

Coolant Control Pad

In the context of energy-savings measures and the needs-based use of resources on machine tools, intelligent control of assemblies is be-

coming increasingly important. The Coolant Control Pad is used to regulate frequency-controlled pumps as well as control valves based High pressure

on needs. It also enables individual pressure control at the relevant lubricoolant nozzle for each lubricoolant consumption point, thereby Example

also controlling the lubricoolant exit speed and volume flow. This device automatically controls how much lubricoolant is discharged (bar)

when and where. Pressure (bar): 6.6

Exit speed (m/s): 15.0

Consisting of a real-time system and innovative calculation software, the Coolant Control Pad can use pressure, exit speed or volume Volume flow (l/min): 206.4 Exit speed

flow parameters on lubricoolant nozzles to carry out control tasks. The lubricoolant exit speed, in particular, is a decisive variable for the Exit speed (m/s) Volume flow (l/min)

machining process, whereas pressure settings are less significant. The target value is stored in the machining program of the machine Outlet cross-section: 250 mm 2 (m/s)

Medium: Oil

and fed via an interface to the lubricoolant control module, which then specifies the precise setting of the pump or valve. This ensures

that the process is always supplied with exactly the right volume of lubricoolant at the right time and with minimum energy consumption.

Low pressure

(bar)

ADVANTAGES

Pressure (bar)

Nozzle-related control of the lubricoolant exit speed at the Grindaix nozzle

Ready - Control active

Cycle-related (roughing/finishing) nozzle supply

Energy-efficient, needs-based lubricoolant supply

Monitoring of the lubricoolant exit speed directly at the Grindaix nozzle

Control independent of the make/type of machine, pump and piping system

High system speed for rapidly changing process cycles

64 65