AI - what is it?

Basically, the concept of artificial intelligence is technically misplaced in this context. Artificial intelligence describes the academic endeavours of humans to research the human brain and its performance and to map it with the help of computer-aided methods.

In connection with the computer-controlled, in future autonomous control of production facilities, the term "machine learning" is correctly used. This means the application of algorithms for efficient and effective learning of goal-oriented production behaviour patterns and the ability to diagnose deviations from these patterns as errors. If, in addition, it is possible to identify the causes that led to this deviation from the "optimal scenario" and to make a recommendation for remedying the cause of the error, this would already be a preliminary stage of the final goal to be striven for - "autonomous production".

In the context of this topic, a wide range of terms are currently used, such as deep learning, IoT (Internet of Things) platforms, virtual assistance, smart robots, augmented reality, digital twin, edge computing, cloud support computing, data mining, predictive analytics, big data, cognitive computing and many more.

Differentiating them all correctly from a technical perspective is not the aim of this series of reports and would go far beyond the scope of this report. It should simply be pointed out that these terms do not necessarily describe one and the same topic - this is very important in order to avoid technical confusion in the study of the following 8th chapters.

Products relevant to this article:

GRX-Q

You may also be interested in these articles from our magazine:

AI - opportunities

The opportunities that arise from the successful use of a production environment that is monitored in line with requirements and controlled by artificial intelligence are diverse and often unexpectedly full of potential.

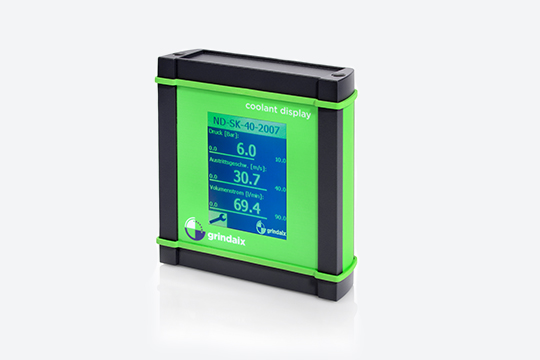

Cooling lubricant pressure control systems

Pressure control systems are particularly relevant for large and complex cooling lubricant supply systems. We have compiled the advantages over conventional pressure control systems and outline the technical implementation of an adequate pressure control system.

AI - Autonomous production

Production technology is increasingly characterized by the use of computer-aided knowledge management systems. A distinction is made between expert systems that pursue a deductive learning approach and inductive optimization methods.

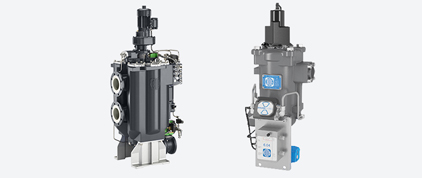

Coolant filtration systems

Treatment is a crucial part of the cooling lubricant supply with a major impact on production results and efficiency. We have described and compared the usual filtration processes for cooling lubricants.