Grinding burn - Important information on recognizing, monitoring and avoiding it

Grinding burn is one of the most common types of damage to a component in manufacturing. The causes can be manifold and must be recognized initially in order to better monitor them in future processes and, with the right approaches, avoid them.

Thermal damage Grinding burn - What is it?

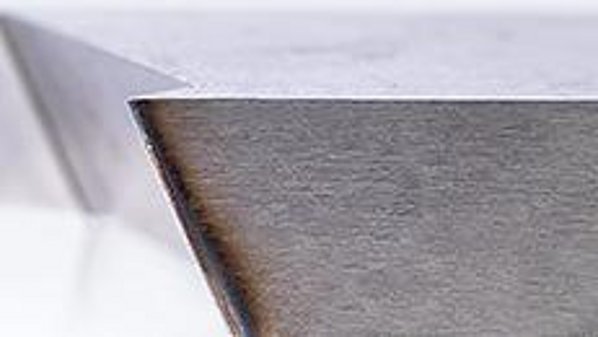

Grinding burn is generally thermal damage to a component. This is caused by an improperly conducted grinding process in which too much process energy is dissipated into the component in the form of heat. The material overheats just as quickly as it cools down. So-called “grinding burn zones” form in the edge structure of the component, which exhibit high tensile stress. If the tensile stresses are increased, this leads to grinding burn-induced microcracks, which grow when the components are dynamically loaded during subsequent use.

The result: subsequent component failure!

Grinding burn - characteristics

- Optical discoloration

- (Micro) cracks

- Loss of hardness

- Power consumption

- Reworking impossible

“Grinding burn is the most common cause of mechanical failure of dynamically loaded functional components”

Causes of grinding burn at a glance

To prevent and avoid grinding burn, it must be recognized and the causes identified. There are many causes of grinding burn, but most cases of grinding burn are caused by the following:

- Poor supply of cooling lubricant to the grinding point

- Excessive chip volume: excessive volume of material that is ground off the grinding wheel per second

- Decomposition of the grinding wheel surface with grinding chips

- Worn grinding wheel condition

However, some of these points can be used very effectively to prevent grinding burn. For example, a suitable and optimally adapted Grindaix cooling nozzle can optimize the supply of cooling lubricant and prevent grinding burn.

Avoiding grinding burns - 2 sensible approaches

To avoid grinding burn, it often makes sense to start by optimizing the cooling system and the grinding wheel itself:

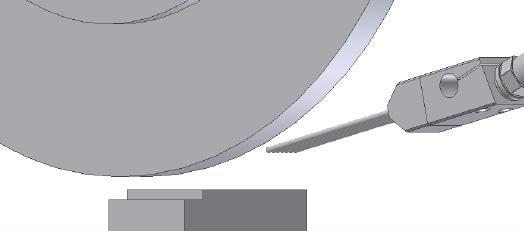

Clean the pore space between the abrasive grains

Furthermore, care should be taken to ensure that the pore space between the abrasive grains of the grinding wheel is always sufficiently large. This allows the optimum amount of cooling lubricant to be absorbed and transported to the grinding zone.

However, a fine grinding wheel with minimal pore spaces is often required for fine surface qualities. These pore spaces quickly become clogged with grinding chips that are wedged between the abrasive grains. The solution to flushing the pore spaces of the grinding wheels?

A grindaix cleaning needle nozzle (pdf)!

The pore spaces are thus freed from superfluous material chips and the cooling lubricant can re-enter the grinding zone. This significantly reduces the likelihood of grinding burns.

Sufficient lubricoolant supply

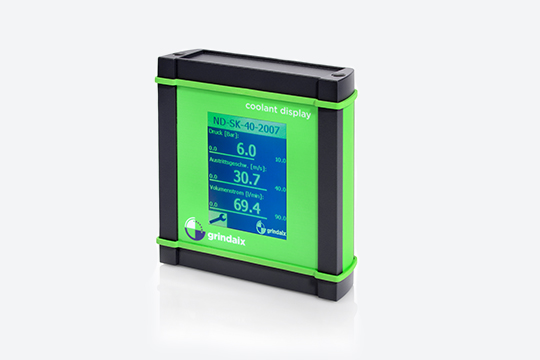

One way to avoid grinding burn is to ensure a sufficient supply of cooling lubricant. This is achieved when a lubricoolant jet is created that has a jet speed of approx. 30-50% of the grinding wheel peripheral speed at the grinding point. Knowledge of the coolant pressure at the nozzle, coolant quantity and speed is also important in order to adequately prevent grinding burn.

Both the jet speed and the above-mentioned characteristic curves are available with every Grindaix needle nozzle. This satisfactorily reduces the risk of grinding burn in all applications.

Further advantages of using a Grindaix nozzle:

- Optimally adapted discharge speed

- Increased productivity

- More resource-efficient grinding processes

- Coolant savings

- Long service life

The most common grinding burn test methods

There are basically many ways to detect grinding burns. These methods are divided into “non-destructive” and “destructive” methods.

The “non-destructive” methods include

Nital etching

This test method is a chemical method. By using nitric acid (HNO3), surfaces that show grinding burn are discolored.

Find out more on our “Grinding burn test method” magazine page!

Barkhausen noise

This magneto-inductive method is flexible and can be used at short notice. Here, the amplitudes resulting from the electrical magnetization are measured and related to the amplitudes of a component free of grinding burn.

You can find more information on our “Grinding burn test procedure” magazine page!

Surface crack detection (PT)

The surface crack test (PT) is a dye penetrant test that is suitable for almost all materials. Here, the test liquid penetrates all surface defects on the workpiece. By applying a developer layer, the test liquid is drawn out again and the defects become visible. These can be both cavities and cracks in the surface.

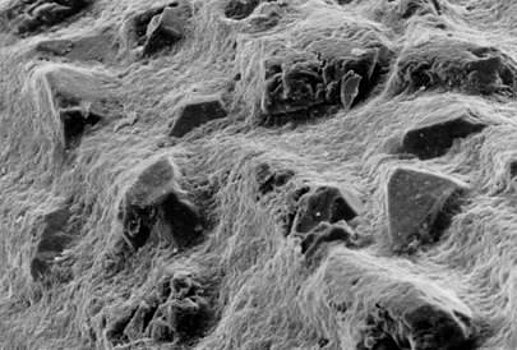

Abrasive belt can be detected more clearly with the “destructive” methods. These include:

Scanning electron microscope image

Here, an electron beam is used to scan the surface. As soon as the electron beam hits the surface, various interactions take place, which provide information about the properties and are evaluated.

Microhardness testing

In this test method, the surface to be tested is a microsection through the component, which is then polished. Grinding burn is then determined by measuring the hardness.

Would you like to know more? Take a look at our “Grinding burn test procedure” magazine page!

Grindaix cooling lubricant nozzles - The best solution to prevent grinding burn!

Not sure how you can prevent grinding burn on the components you produce? Convince yourself of our service and our ingenious products. Request an individual offer and a nozzle proposal for your process by e-mail with our questionnaire for needle nozzle design (pdf).

You can look forward to receiving a high-quality nozzle prototype or a corresponding nozzle package on the desired delivery date. Try it out - you will be surprised at how little effort you can avoid grinding burn!

You can find more information about our needle nozzles under Coolant Nozzles or in the download area.

If you have any questions about our products and services, please do not hesitate to contact us. You can reach us on weekdays from 8 a.m. to 5 p.m. by e-mail at info@grindaix.de or by telephone on 02273 95373 0.

Your questions - Our answers

What types of nozzles are available at Grindaix GmbH?

Grindaix GmbH offers a wide range of nozzles that are specially designed for different applications. These can be cooling, cleaning, flushing or special nozzles. In order to tailor the variety of nozzle types precisely to your production situation, we plan, design and produce individual cooling lubricant nozzles.

What if grinding burn is not recognized?

If grinding burn is not recognized and avoided or is vehemently dismissed as a coincidence, it can cause considerable damage to the component. This can result in component failure, rendering the component unusable for later use.

Why is grinding burn bad?

If there is grinding burn on a component, so-called microcracks can also form in the component. Microcracks grow when the components are subjected to dynamic loads during subsequent use. This then leads to the component breaking and it can no longer be used for its intended purpose.

How does grinding burn develop?

Grinding burn is the result of excessive temperature input into the component. This is caused by incorrect and insufficient cooling in the machining zone between the component and the grinding wheel.

Can you see grinding burn with your eyes?

Grinding burn is often difficult to detect with the naked eye and only in particularly bad cases. For this reason, it is necessary to carry out “grinding burn tests” to detect grinding burns. These can be both non-destructive and destructive methods.

Products relevant to this article:

You may also be interested in these articles from our magazine:

Grinding burn test

Detection of grinding burn is an important pillar of quality assurance, as grinding burn is not always immediately visible on the component. We explain which methods are available for this and explain their applicability.

Solving grinding burn problems

Solving a shelf edge problem? That's easier said than done! We have developed some solution strategies and summarized them for you in our magazine article on “Solving sanding burn problems”.

Grinding technology

Our article “Grinding technology” provides an overview of the complex topic of grinding technology with its many influencing factors. Here we offer you a complete overview of all relevant parameters.

Cooling the grinding process correctly

Cool the grinding process properly! This is easier said than done. We have compiled a list here of the various parameters that need to be taken into account and which supply solutions are suitable or unsuitable.