AI - opportunities

The possibilities resulting from the successful use of a production environment that is monitored according to requirements and controlled by artificial intelligence are manifold and often unexpectedly high in potential.

Electronic data processing systems for the optimization of production processes learn or work non-stop and make correctly trained, fewer mistakes than a human being. They optimize the entire dynamically acting and increasingly complex and extensive production system, not the individual machine, in a way that we humans simply cannot do at the same time.

Artificial intelligence (machine learning) usually proceeds inductively - means probabilistically (algorithms) and finds optimization goals that we humans (technical experts) do not suspect (because we usually only think deductively (technical knowledge/formula work) in single machine solutions and increasingly cannot grasp the overall complexity in accordance with requirements or master it in real time.

Furthermore, there may not be enough technical experts in the future - then the use of assistance by artificial intelligence (machine learning) would be the "only" choice to remain successful in the long term. An insufficient number of technical experts could very probably be justified in the future for demographic reasons, but also for reasons of maximum economic efficiency resulting from the use of artificial intelligence, which in turn would make "full employment" desirable. In both cases, the use of software-based production assistance systems based on algorithms that have been trained over many years would be necessary for the continued existence of production profitability.

In addition to increasing productivity (number of good parts per time) while maximizing profitability (operating result) in general, there are in principle no limits to the possibilities of using artificially intelligent production optimization systems beyond this. Optimization targets can be defined and programmed individually for each company. For example, there are sub-areas of production engineering where the quality of safety-relevant components is the main focus, rather than the most cost-effective production.

Products relevant to this article:

You may also be interested in these articles from our magazine:

AI - How do you proceed?

The first step in this context is to start implementation as soon as possible and not to wait until a competitor can present a solution. Because this solution, if it is available at all, certainly cannot simply be copied or purchased at the touch of a button.

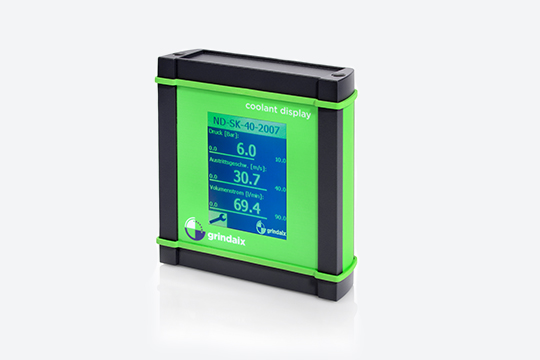

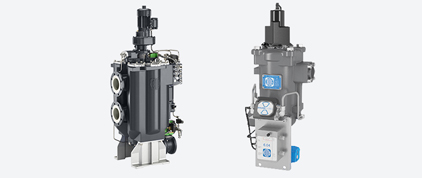

Coolant filtration systems

Treatment is a crucial part of the cooling lubricant supply with a major impact on production results and efficiency. We have described and compared the usual filtration processes for cooling lubricants.

AI - challenges

As already described in Chapter 3 (AI - How to proceed), the algorithms for the successful application of machine learning in production technology require as much good data as possible. Good data is data whose values are generally as correct as possible.

Frequent problems during grinding

Modern high-volume production facilities for metal components often have large and equally complex cooling lubricant systems. Keeping an eye on all parameters and ensuring reliable operation is therefore no trivial matter. Coolant monitoring systems can be used to support the monitoring of the cooling lubricant system.