AI - Implementation

The following example demonstrates how a digitalization project can be successfully implemented.

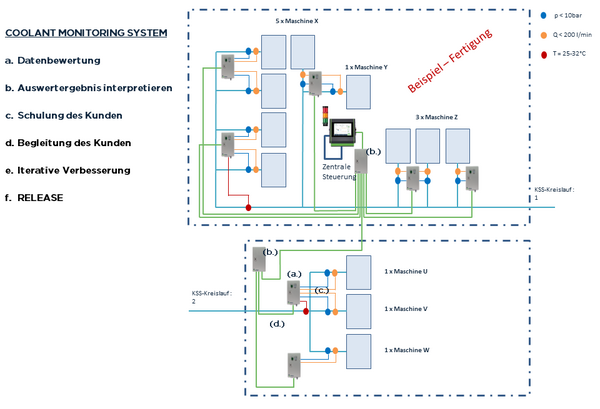

Auditing the production system: In a first step, the user formulates the respective production components to be monitored (What is to be monitored?) and the expected monitoring results (What information is expected from the production monitoring system, in what form and which output data formats?)

In the second step, Grindaix GmbH analyzes the feasibility of the customer's requirements on site via the logical linking of various possible sensor signals at different points of use (accessibility, insertion, signal interfaces, ...) within the KSS system.

The signal interfaces in particular must be selected very carefully. Grindaix GmbH carries out a detailed Coolant Audit-E (electronics), in which the interfaces of all notified cooling lubricant system components are analyzed for suitability and provides specific conversion recommendations (circuit diagram, parts list, hardware, software) exactly where the interfaces for the connection of a cooling lubricant monitoring system are not yet designed to meet the requirements.

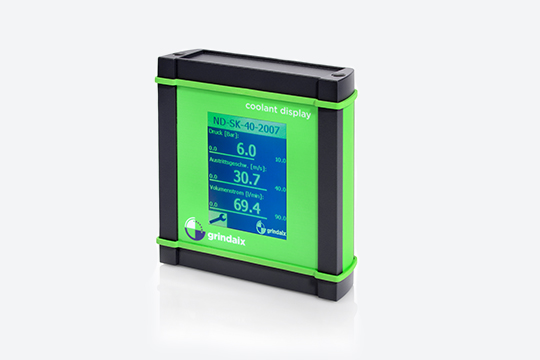

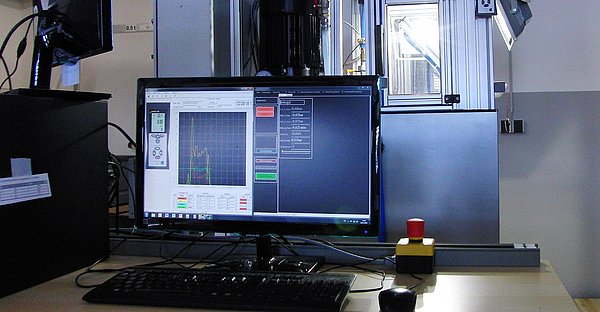

The necessary interfaces are then created or used in the customer's production system. The sensors are integrated into the production system, wired and linked to a higher-level control center (condition monitoring pad).

The condition monitoring pad is the control center of the production monitoring system and is used for the central recording of all installed sensor signals. The software defines upper and lower limit values for when a sensor signal value can be identified as an error. So-called plausibility scenarios are then programmed, which formulate statements based on the logical correlation of various production sensor signals that go beyond the individual condition monitoring of a production component (see, for example, the differential pressure loss in pipelines described above). The sampling rates are also determined, i.e. how often a sensor signal is to be measured and recorded (saved) in order to enable subsequent production data tracking (GRX-PDT).

When the system is commissioned, test runs are carried out that do not affect production operation (“read” status!). Limit values are adjusted, measurement series are recorded and analyzed for test purposes. The learning (teach-in) phase of the production monitoring system begins. In a subsequent interaction phase, depending on customer requirements, the control mechanisms can be successively activated to enable adaptive control of the production components. Once this process is complete, the production monitoring system is accepted. The employees are trained in the handling of the monitoring system and instructed in the maintenance options.

It must be avoided at all times that the sensor integration described here makes the production system too susceptible to possible measurement errors. For this reason, the monitoring system can initially only work on a “read-only” basis and sends error messages to a higher-level control center without intervening in the production process. Further monitoring systems specifically control a wide range of variables within the production unit in order to maintain the customer's desired lubricoolant supply at all times..

Interfaces to machines as signal setpoint transmitters (e.g. pressure demand cycles on frequency-controlled pumps) almost always have to be created. In most cases, these are not available and the system supplier does not allow any intervention in its system electronics without issuing a warranty. Therefore, such interfaces must be provided either via Profinet/bus interfaces (bus systems) or by means of isolation amplifiers to ensure galvanic isolation of the electrical signals, either via suitable service providers or via the system supplier itself.

Galvanic isolation or decoupling refers to the avoidance of electrical conduction between two circuits between which power or signals are to be exchanged. This prevents any influence on the electrical circuit of the signal transmitter (machine tool, filtration system, pump, etc.).

This additional effort leads to a higher investment volume and initially represents an obstacle to the implementation of digitized system technology. However, if the benefits can be calculated, a specific amortization period can be determined without the use of artificial intelligence.

Products relevant to this article:

You may also be interested in these articles from our magazine:

Coolant filtration systems

Treatment is a crucial part of the cooling lubricant supply with a major impact on production results and efficiency. We have described and compared the usual filtration processes for cooling lubricants.

AI - What is it?

Basically, the term artificial intelligence is a technical misnomer in this context. Artificial intelligence describes the academic endeavors of humans to research the human brain and its performance and to reproduce it with the help of computer-aided methods.

AI - Risks

In addition to the many good opportunities and high potential benefits of artificial intelligence in production technology, there are also risks that need to be considered when implementing such capability tools.