Coolant supply during centerless grinding

Among the cylindrical grinding processes, the centerless processes occupy a special position with regard to their process design and their range of applications. The main area of application for centerless grinding is in large-scale and mass production.

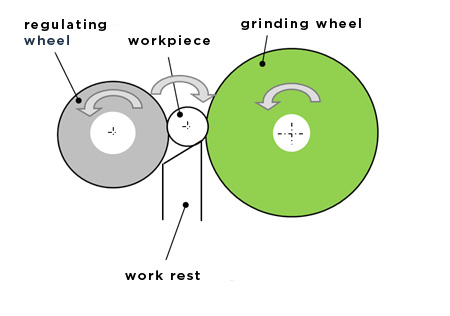

While the workpiece is guided on its axis of rotation between centers during grinding, its position is determined by a three-point support on the grinding wheel, regulating wheel and support rail components during centerless grinding. The component is simultaneously guided and machined on its circumferential surface.

Centerless plunge grinding

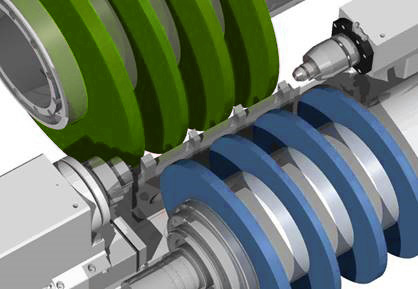

In centerless plunge grinding, the components to be ground are fixed in position by means of an axial stop, and in height on a support rail. The grinding wheels are usually arranged in packets on the grinding spindle and grind all the functional surfaces of the component in a plunge-cut grinding process in a single step. This saves time. The component is supported by a regulating wheel to prevent it from bending. At the same time, the regulating wheel slows the component to a process-compliant level.

The cooling lubricant supply has various tasks in centerless plunge grinding:

- Supply of all active grinding wheel facing areas that come into direct contact with the component

- Cleaning of the active grinding wheel facing areas from material-related clogging

- Penetration of the air cushion rotating with the grinding wheel

- Avoiding an aqua-planing effect due to coolant oversupply

- at the contact zone between the component and the support rail

- at the contact zone between the component and the control wheel

- Cooling of the dressing process

- Removal of grinding sludge from the machine bed

- Cooling of the machine bed / machine structure

- Cooling of the grinding spindle

- Cleaning of the measuring devices in the machine compartment

All these different supply tasks must be taken over by a professionally designed cooling lubricant, without foaming and improper deposits in the machine room. The purity of the cooling lubricant for centerless grinding should not exceed a gravimetric residual dirt content of 50 mg/liter. This gravimetric residual dirt content is measured with a membrane (maximum pore size 5µm).

The number of particles in different size ranges is determined provisionally using DIN ISO 4406 (for emulsions) and NAS classes (for oils).

Grindaix KSS nozzle technology is mainly aimed at tasks 1 to 3:

- Supply of all active grinding wheel contact areas that come into direct contact with the component

- Cleaning of the active grinding contact areas from material-related clogging

- Proper penetration of the air cushion rotating with the grinding wheel. In centerless plunge grinding, when the support table is tilted, some areas of the workpiece are machined on a planer shoulder during the plunge cut.

In centerless plunge grinding, when the support table is tilted, some areas of the workpiece are machined on a planer shoulder during the plunge cut.

This involves high contact lengths between the component and the grinding wheel, which makes it difficult to supply the grinding point with coolant. For this case, Grindaix uses a patented nozzle principle (see also the All in One nozzle GRX-X) in which the abrasive coating areas of the grinding wheel are supplied separately. The air cushion rotating with the grinding wheel is skimmed off by means of a first nozzle stage. In a second step, the grinding wheel is cleaned. The coating appears fresh and clean and remains easy-cutting for longer without the need for dressing. In a third step, free pore spaces in the grinding wheel are soaked with cooling lubricant immediately before the grinding wheel comes into contact with the component. This means that the grinding wheel itself transports the cooling lubricant to the grinding zone. The last and fourth task of the Grindaix patented solution is the process cooling from the outside, which, due to the fact that the air cushion has been significantly weakened beforehand, can now also be achieved much better in shoulder grinding areas.

To prevent these nozzle systems from becoming resinous (when using an emulsion), they must be briefly blown out after use via a separate compressed air supply to the Grindaix nozzles. To do this, a compressed air valve is opened directly by the machine control system for a short time after the process has been completed.

Centerless through-feed grinding

In centerless through-feed grinding, the component does not remain on the support rail, but moves over it through the gap between the grinding and control wheel and the support rail. The outer diameter of the part is to be ground to a required dimension. The advantage of this method is that the parts can be passed very quickly through the grinding area without the time required for changing parts. This saves time.

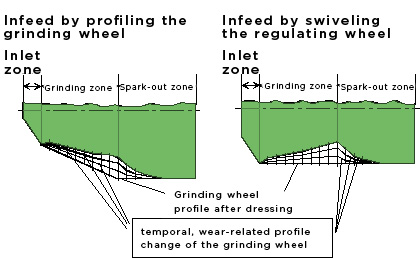

The removal of the workpiece allowance must therefore be distributed over the available grinding wheel width. Nevertheless, a characteristic wear for centerless through-feed grinding processes will develop along the grinding wheel axis, which is also known as the “centerless hole” (Fig. 2). This wear occurs regardless of whether the grinding gap conicity is produced by a corresponding profiling of the grinding wheel or swiveling of the regulating wheel [KOEN84].

The grinding wheel can be divided into axially parallel sections based on the axial feed per workpiece rotation. In the grinding zone, each area of the width must remove part of the workpiece stock. If a section of the grinding zone wears, the following section is then presented with workpiece material in addition to the stock, which could not be removed by the previous area. The grinding wheel wear in the grinding zone increases in the feed direction because each grinding zone section has to compensate for the wear of the previous section. In the spark-out zone, the wear decreases again, which is why the centerless hole between the grinding and spark-out zone is formed.

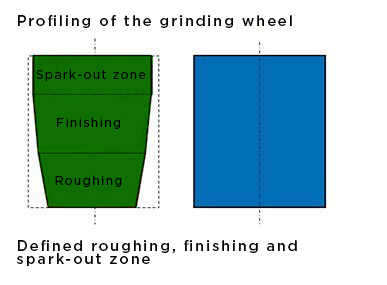

This means an additional task for the cooling lubricant supply. The cooling lubricant supply is handled differently (in pressure and supply quantity) across the width of the grinding wheel. There are three cooling lubricant supply areas, see Figure 5.

The component passes through the areas of roughing, finishing and final sparking out in the grinding gap of centerless through-feed grinding. Particularly when the workpiece enters the grinding gap, there is an abrupt increase in material removal. This area is called the roughing zone, where the so-called roughing is carried out. Roughing is understood to mean maximum machining of the stock allowance without taking into account the surface quality that is formed in the process. Here, particularly strong cooling is required, as high temperatures arise due to the high material removal rate. On the one hand, the component must be protected from thermal damage, while on the other hand, the tool-side wear caused by the previously mentioned “centerless hole” can be significantly reduced by improved cooling. The tool wears less quickly and the process can be carried out more stably for longer. This increases the profitability of the manufacturing process.

Solution from Grindaix GmbH

Similar to centerless plunge grinding, the patented multi-functional nozzle approach maximizes the professional supply of coolant to the grinding process via the four-fold functional approach, especially in the roughing area of a grinding wheel. Each Grindaix nozzle solution is designed for your process and professionally optimized.

Fourfold functional approach

- Reduction of the influence of the air cushion (weakening)

- Cleaning of the active abrasive areas of material-related clogging

- Impregnation of the rough grinding wheel coating

- Appropriate penetration of the cooling lubricant jet of the air cushion rotating with the grinding wheel

Optimization goals

- Reducing the risk of grinding burn at maximum productivity

- Stabilization of the grinding process (robustness) through wear-reducing effects on the grinding tool

- Reducing the need for cooling lubricant – relieving the load on the cooling lubricant filtration system

The finishing and spark-out areas of a grinding wheel during centerless through-feed grinding can be supplied conventionally using the existing Grindaix nozzle solutions (needle nozzle, centerless nozzle). In the finishing area of the grinding wheel, attention is paid to surface formation rather than material removal, in contrast to the roughing area. The supply of coolant to the finishing wheel is significantly lower (pressure/quantity) than is the case in the roughing area. Hardly any coolant is needed in the spark-out area, since very little, if any, machining occurs here. As a result, no thermal damage to the component surface is to be expected.

Sources:

KOEN84 : König, W.; Schleich, H.; Yegenoglu, K.; Stuckenholz, B.: High performance grinding with CBN-wheels, Biennial International Machine Tool Technical Conference – Session 5, S. 58 – 96, IMTS 84, Chicago, USA

Products relevant to this article:

You may also be interested in these articles from our magazine:

Zero Emission Production

Zero Emission Production helps to sustainably reduce carbon dioxide emissions while increasing the availability of production equipment and avoiding the waste of operating materials.

GRX-Q - Magnetic-inductive flow measurement

In magnetic-inductive flow measurement (MID), an electrical voltage is generated by the interaction between the flow velocity of a liquid and a magnetic field. This principle is based on Faraday's law of induction.

Process design and optimization:

The change in the automotive industry and the targeted reduction of CO2 emissions, e.g. in aviation, pose new challenges for grinding technology. The machining of thin-walled lightweight components and the machining of high-temperature materials are becoming increasingly important.