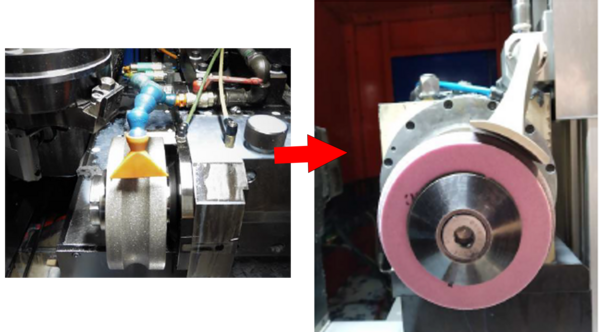

The various nozzle technologies from Grindaix GmbH have proven themselves in practice many times over and have significantly improved data in the grinding process. For example, considerable optimization has been achieved in internal cylindrical grinding processes thanks to tailor-made 3D-printed nozzles. Among other things, because 3D printing enables a very slim design.

By optimizing the nozzles, the total consumption of the machine could be reduced by up to 51 l/min (approx. 30%). At the same time, the coolant outlet speed at the nozzles was increased from 5.9 m/s to 11.6 m/s - 14.5 m/s compared to the previous LocLine nozzles, thus increasing it by 96 % to 145 %. By throttling the machine bed, cooling lubricant consumption during dressing and flushing was also reduced by 20%. The optimization prevented the previous grinding burn and also increased productivity (cycle time) by 15%!

Here you can see the grinding process data before and after nozzle optimization:

![[Translate to Englisch:] Schleifprozess-Werte Vergleich [Translate to Englisch:] Vergleich Werte mit und ohne Grindaix-Düse](https://grindaix.de/fileadmin/Public/Archiv/Schleifprozess-Werte.png)

![[Translate to Englisch:] Magazin-Teaser [Translate to Englisch:] Expertenwissen und Qualität im Grindaix-Magazin](https://grindaix.de/fileadmin/_processed_/c/8/csm_grindaix_magazin-teaserbild_2.1_b87e87b618.png)