Lubricoolant Dual Nozzles - Two Functions - One Nozzle

With our special Grindaix Dual Nozzles, it is possible to clean the machining site efficiently, while at the same time ensuring sufficient lubricoolant supply to the grinding process in order to effectively cool the machining site.

Just before the machining site, clogging on the surface of the grinding wheel is eliminated and the free pores are filled with lubricoolant. The Dual Nozzles are suitable for use with both oil and emulsion. The nozzle profile can be supplied for all worm wheel and gearwheel geometries.

The Dual Nozzle can be used during various grinding processes, such as surface, profile and generating grinding. Thanks to the rotary motion of the cylindrical worm, the lubricoolant is then guided into the machining site. The combination of cleaning and cooling has several advantages for the grinding process:

- Unwanted foreign particles are rinsed out of the grinding wheels at high pressure before the machining site.

- Free pores are filled with fresh lubricoolant.

- More lubricoolant enters the machining site (better cooling results).

The Grindaix Dual Nozzles are equipped with needle nozzles and special cleaning nozzles.

By means of the needle nozzles, the lubricoolant enters the machining site in a targeted way and with a high exit speed (dependent on the grinding process). The cleaning nozzles are optimally aligned to the grinding wheel, thoroughly rinsing away impurities from the workpiece and/or grinding wheel. The Dual Nozzles may be aligned with the aid of the Cooolant Pointer. This is positioned on the provided holders and allows very precise setting of the needle nozzles. Precise alignment is important, so that the lubricoolant jet enters the machining site and does not end up in the lubricoolant cycle in an unused state. For more information, please consult our flyer (pdf). Should you have any questions on our Dual Nozzle technology, our lubricoolant specialists would be more than happy to help.

The combination of Dual Nozzle functions at a glance:

- Cooling & cleaning

Available for the following processes:

- Surface grinding

- Profile grinding

- Generating grinding

- Cylindrical Grinding

- …

| Name | Type | Size | Download |

|---|---|---|---|

| Grindaix - Questionnaire needle nozzle design 2024 | 641 KB | download |

Product inquiry

We would be happy to provide you with more detailed information on your desired topic. Simply send a non-binding inquiry to info@grindaix.de, and we will get back to you as soon as possible.

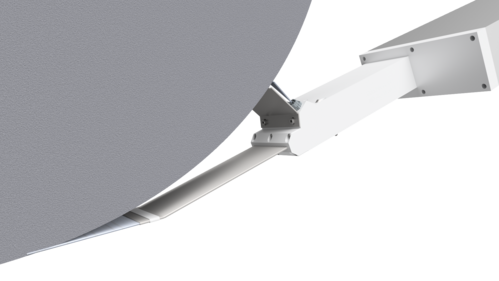

Examples of our dual nozzles in use

The KSS dual nozzles from Grindaix GmbH combine the functions of cooling and cleaning nozzles and are developed individually for each grinding process. The use of a single nozzle for several functions not only saves space, but also increases productivity and component quality. This can be used in all grinding processes and thus cover a wide range, from surface grinding to dual generating grinding.

Advantages of a coolant dual nozzle for grinding processes:

- Cooling and cleaning nozzle in combination

- Lubricoolant outlet speed in line with requirements

- High jet quality (laminar) to penetrate the air cushion

- One lubricoolant supply line for multiple functions

- Cleaning the grinding wheel

- Cooling the grinding zone

- Space-saving

Surface grinding

Surface grinding is a grinding process in which flat and often large surfaces are ground. The aim is to smooth the surfaces after the actual machining process, such as milling. However, this process results in long contact lengths between the component and the grinding wheel and high processing temperatures. Chips and impurities can also remain. It is therefore important that foreign bodies are removed and good cooling is ensured. The Grindaix dual nozzle ensures both aspects! Unwanted foreign bodies are flushed from the machining zone and the grinding wheel is cleaned and soaked with cooling lubricant. At the same time, cooling lubricant is supplied in a targeted manner and at a high discharge speed.

Camshaft grinding

One type of cylindrical grinding is camshaft grinding, which involves various difficulties with the supply of cooling lubricant. The engagement conditions and therefore the position of the grinding points change more frequently. This makes an adequate supply of coolant difficult. High temperatures also occur below the machining zone, which increase risks such as grinding burn or machine fires. The lubricoolant dual nozzle from Grindaix GmbH helps to optimize the difficult process cooling by combining a cooling and cleaning nozzle. The cleaning nozzle soaks the grinding wheel and transports lubricoolant into the machining zone, while at the same time removing chip residues, which is important when the contact conditions are constantly changing. The cooling nozzle, on the other hand, precisely feeds cooling lubricant to the machining zone.

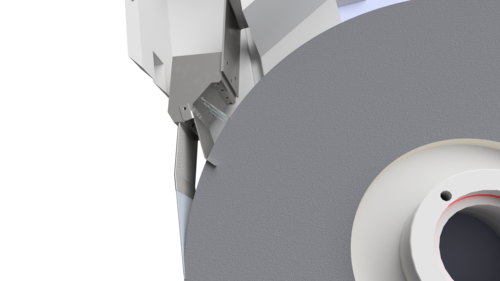

Dual generating grinding

In dual generating grinding, two rotating grinding wheels act simultaneously on a workpiece to precisely machine the surfaces. However, the rotation of the wheels and the heat generated in the process require an effective coolant supply to prevent overheating and material changes without any adverse effects. The experts at Grindaix GmbH have developed dual nozzles for this purpose! The dual nozzles transport cooling lubricant directly and indirectly to the machining zone. On the one hand, the lubricoolant jet penetrates the air cushion at a high exit speed and reaches the machining zone, and on the other hand, impurities on the grinding wheel are rinsed and free pores are soaked with lubricoolant. This ensures that both sides of the workpiece to be machined are supplied with sufficient lubricoolant.

Flat profile grinding

Flat profile grinding is used to process workpieces with complex, non-straight or profiled surfaces. A grinding wheel with a specific profile is used for this. The continuous contact between the grinding wheel and the workpiece leads to increased heat generation, which requires adequate and targeted cooling. The dual nozzles are designed for such grinding processes and ensure a precise supply of cooling lubricant. Heat generation is reduced by combining the cooling and cleaning nozzle. The cooling nozzle penetrates the air cushion and delivers the coolant precisely to the machining zone. The cleaning nozzle cleans the grinding wheel and fills the free pores with coolant so that the grinding wheel transports the coolant to the required location. This ensures sufficient cooling even when grinding complex and profiled surfaces.

Would you also like to improve your grinding process?

Make an inquiry today!

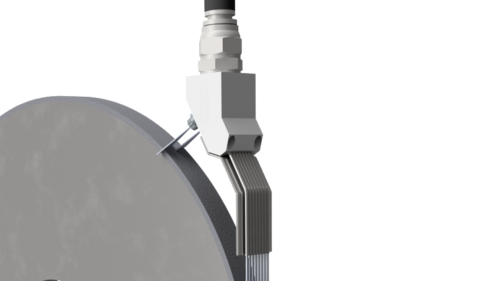

Equipment for the Grindaix dual nozzles

The Grindaix KSS dual nozzle requires suitable equipment (accessories) in order to optimally increase productivity and longevity. However, assembling these accessories can often be more difficult than initially thought. We have therefore developed accessories that meet all requirements and are specially designed for Grindaix nozzles! With the Coolant Protectors from Grindaix GmbH, almost all nozzle geometries can be effectively protected. They offer solutions for wear protection, air drainage and stabilization. In addition, devices such as the coolant pressure gauge, the coolant display and the coolant pointer have been developed to make the alignment and display of your coolant data faster and more precise. The quick-change systems also enable the uncomplicated and practical exchange of nozzle variants and gFlex lengths.