Grindaix nozzles for (bed) flushing

- Nozzles Prevention of chip deposits in the machine bed

- Considerable cleaning effect with low lubricoolant volume

- Angles and corners are flushed clean

- Reduction in manual cleaning work

- Easy assembly

During operation of a machine tool, chip residues collect in the machine bed. These often need to be removed laboriously by hand, as in the worst case these deposits can even lead to machine failure. Furthermore, due to altered lubricoolant flow conditions in the machine bed, the thermal growth of the machine is impaired and production errors result.

Cleaning with lubricoolant is one way of preventing undesired chip deposits in the machine bed as well as on measuring probes, covers and steady rests.

However, completely unsuitable solutions are often used for machine bed flushing, such as clamped pipe ends which are adjusted via a plastic ball valve. The correct orientation of the lubricoolant exits likewise has a decisive effect, as the wrong positioning and dimension mean that not all areas are flushed reliably. Overall this leads to unnecessarily high lubricoolant consumption with inadequate cleaning performance in most cases. High costs for an unreliable flushing process are the result, as every litre of lubricoolant which is consumed must be cooled and and cleaned, and this costs you money – caused by badly designed machine bed flushing!

Our experienced nozzle specialists have developed Grindaix nozzles to design the flushing of your machine tool efficiently and effectively.

Flushing nozzles from Grindaix are characterized by their outstanding cleaning performance and minimal lubricoolant consumption. We can optimize your machine bed flushing system by means of channel flushers designed as a slotted nozzle, or by means of a rotating corner flusher. Our nozzle solutions for flushing applications are, of course, customized to your particular application. We supply flushing nozzles in all required widths.

Grindaix nozzles are robust and durable, as they are made exclusively from high-quality, wear-resistant materials. To exploit the full savings potential of our Grindaix cleaning nozzles, we recommend using machine bed flushing only when the machine is not in operation.

Our experienced nozzle specialists have developed Grindaix nozzles to design the flushing of your

machine tool both efficiently and effectively.

- low lubricoolant consumption

- easy assembly

- less maintenance work

Our nozzle solutions for flushing applications are, of course, customised to your particular application. We supply flushing nozzles in all required widths.

| Name | Type | Size | Download |

|---|---|---|---|

| Grindaix - Questionnaire needle nozzle design 2024 | 641 KB | download |

Produktanfrage

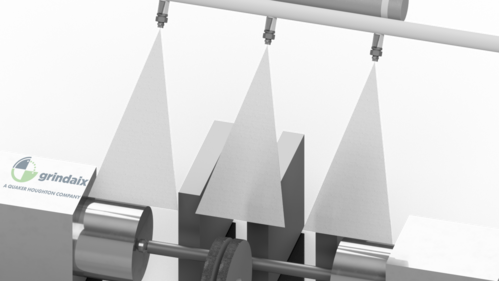

Example of Grindaix flushing nozzles in use

The Grindaix nozzles for (bed) flushing are customized to your specific application. In addition, different areas such as the machine bed or the channels in the machine are taken into account and cleared of chips, so that chip residues no longer have to be laboriously removed in between operations.

Advantages of a flushing nozzle for grinding processes:

- Removal of chip deposits in machine beds, measuring probes, covers, and steady rests

- Reliable flushing

- Excellent cleaning performance

- Reduces coolant consumption

- Durable and robust

Grinding

Grinding is a machining and shaping manufacturing process in which the surface of components is machined to ensure high surface quality, for example. During this process, however, many chips are removed from the material and end up on the component, machine bed, measuring probes, or covers. To prevent these chips from interfering with the manufacturing process by altering the coolant flow conditions in the machine bed, which can impair the machine's thermal behavior or even lead to machine failure, it is important to remove the chips. The specially developed flushing nozzle from Grindaix GmbH flushes the machine and all components free of chip residues, thus improving its longevity. In addition, the component is protected from manufacturing errors caused by faulty machine heat flow.

Would you like to remove chip deposits from your machine?

Submit an inquiry today!

Equipment for the Grindaix dual nozzles

Equipment specially designed for Grindaix nozzles, such as Coolant Protectors, can protect and stabilize almost all nozzles against wear and tear and dissipate air. In addition, cooling lubricant data can be displayed more accurately and alignment can be made faster by using specially developed systems such as the cooling lubricant pressure gauge, the Coolant Display, and the Coolant Pointer. The quick-change systems also enable easy replacement of different nozzle variants and gFlex lengths. With the right equipment, the productivity and longevity of nozzles can be effectively increased without the challenge of different combinations..