Coolant Protectors – We Protect your Nozzles!

- optimum protection from abrasion wear

- protection from damage during assembly/disassembly work

We can provide almost all nozzle geometries with wear protection. Here we differentiate between

1. Protection from Abrasion wear

Wear plates optimally protect our lubricoolant nozzles against the abrasive effect of the exit jet which contains grinding grains and chips which rotates with the grinding wheel. For highly abrasive applications, the wear plates may be supplied with an ultra-hard wear protection coating depending on their geometrical design.

2. Protection from Damage during Assembly/Disassembly Work

Our metal stabilizers protect the needles and hold them in a stable position. They may be used at nozzle ends and also in the middle of the needle length in the case of very long needles.

Our wear plates are available in all widths and geometries. We look forward to your enquiry!

| Name | Type | Size | Download |

|---|---|---|---|

| Grindaix - Questionnaire needle nozzle design 2024 | 641 KB | download | |

| Grindaix - Wear-Resistan Plate and Stabilizers 2024 | 206 KB | download |

Product inquiry

We would be happy to provide you with more detailed information on your desired topic. Simply send a non-binding inquiry to info@grindaix.de, and we will get back to you as soon as possible.

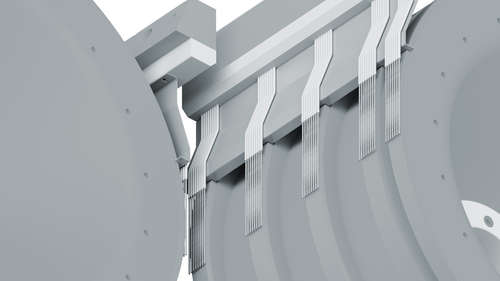

Example of the Coolant Protector in use

The Grindaix Coolant Protector can be quickly, easily and individually adapted to any cooling lubricant nozzle. The stabilizer between the needles holds them in position so that a targeted and precise coolant supply can be guaranteed. The plate also protects against damage caused by flying chips or wear and directs the air caused by the grinding wheel away from the lubricoolant jet. There are no limits in terms of nozzle geometry, so the Coolant Protector can be used in almost any grinding process, such as Inter-center grinding.

Advantages of installing a Coolant Protector:

- Wear protection

- Air drainage

- Stabilization

- Adaptable to all nozzles

- Durable and highly durable

Inter-center grinding

Inter-center grinding is a type of cylindrical grinding in which the workpiece is clamped between centers on both ends. However, a safety driver makes it difficult to machine the workpiece over its entire length and the lubricoolant supply can also be impeded by the safety driver and the inner edge of the grinding wheel shape. Furthermore, chips can fly around due to the movement of the grinding wheel and damage the nozzles or their needles so that they are no longer aimed at the machining zone. The Grindaix Coolant Procetor protects the needle nozzle from such damage and at the same time directs air generated by the grinding wheel away from the coolant jet. This ensures a targeted and long-term supply of cooling lubricant.

Would you like to protect your nozzles from damage?

Make an inquiry today!