Needle nozzle for cooling lubricant supply

- No grinding burn

- Reduction in grinding costs

- Reduction in coolant requirements

- Longer tool life

- Higher productivity

- Optimum cooling of the process

- smaller lubricoolant filtration facilities

- smaller cooling lubricoolant systems

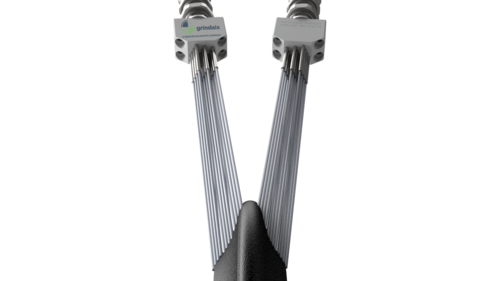

More precise, simpler, more effective: our Grindaix nozzles are not catalogue products, but individually adapted coolant nozzles that are precisely matched to the respective machine! We offer these for all manufacturing processes. With the Grindaix nozzle, the cooling lubricant is supplied to the cutting point in a targeted manner and in the exact and required dosage. The coolant is discharged at high speed so that it is effectively transported to the cutting point and grinding burns on your components are effectively avoided!

Our highly durable nozzles are suitable for use with various oils and emulsions and increase tool life by up to 30 %. At the same time, the cycle time and productivity of your production are increased.

We adapt cooling lubricant supply systems to your needs, both in terms of the application and the process. We take into account the component geometry as well as the coolant's volumetric flow rate, pressure and discharge velocity.

Not only new machines, but also existing ones can be equipped with Grindaix nozzles and optimized. For older machines, a retrofit is worthwhile and the investment usually pays for itself after only a short time.

We will develop a customized nozzle solution for your application as well!

Our specialists look forward to receiving your enquiry!

- High coolant outlet velocity

- Targeted coolant supply to the cutting point

- Improves cooling

- All profile-adapted nozzle shapes for all manufacturing processes

- Optimal coolant use in terms of pressure, volume flow, outlet velocity

- Reduction of filtration volume

- Reduction of tool wear

- Increase in your productivity

- Avoiding waste

- Improvement of your carbon footprint

- Compatible with the Grindaix gFlex articulated hose system

| Name | Type | Size | Download |

|---|---|---|---|

| Coolant Supply Systems for Bed Flushing | 224 KB | download | |

| Coolant Supply Systems for Crankshafts | 170 KB | download | |

| Coolant Supply Systems for Generating Gear Grinding | 438 KB | download | |

| Overview Needle Nozzles Product Catalogue | 3.043 KB | download | |

| Questionnaire needle nozzle design | 3.390 KB | download |

Product inquiry

We would be happy to provide you with more detailed information on your desired topic. Simply send a non-binding inquiry to info@grindaix.de, and we will get back to you as soon as possible.

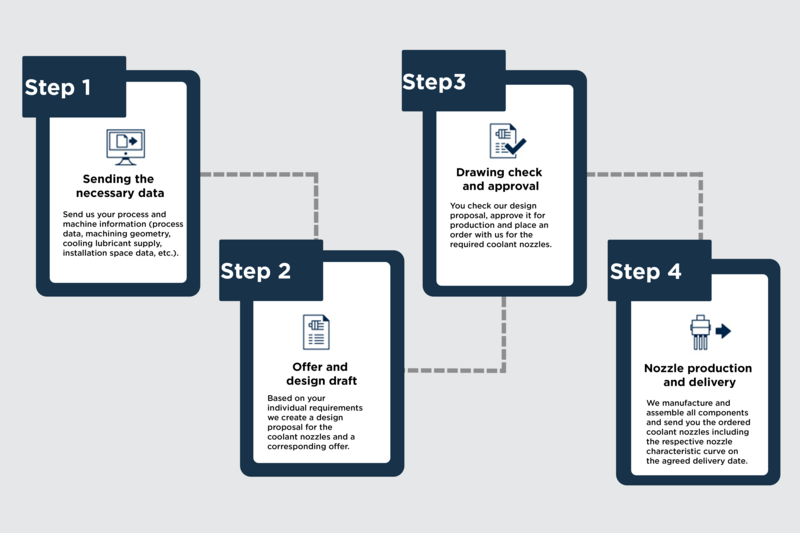

This is how you get your customized nozzle(s)

Each nozzle is specially designed for your application. Therefore, we need detailed information about your process and machine before construction. We then plan a customized needle nozzle. You can see the process here:

Examples of our coolant nozzles in use

Grindaix GmbH offers coolant nozzles for a wide range of grinding processes. This means that all your grinding processes, from centerless grinding to gear profile grinding and internal cylindrical grinding, are effectively protected against grinding burn.

Advantages of our product for all grinding processes:

- Reduced risk of grinding burn

- Increased productivity

- Targeted and even cooling lubricant supply to the contact zone

- Optimal cooling lubricant supply despite complex geometries

- Customized adaptations to your process

- Increase in product quality

- Reduction of coolant consumption

- Coolant discharge velocity as required

- Compact design

Centerless grinding

In centerless grinding, the workpiece is held in a fixed position by a three-point support system consisting of the grinding wheel, regulating wheel and support rail. The coolant supply has several direct tasks here. First and foremost, all active grinding wheel surfaces that come into direct contact with the component must be cooled and cleaned. However, other important tasks in centerless grinding include penetrating the rotating air cushion and discharging grinding sludge from the machine bed. An oversupply of coolant should also be avoided with the three-point bearing, as otherwise an aqua-planing effect may occur. With the nozzles developed by our experts, centerless grinding with its diverse requirements can be optimally supplied. We know from experience: With centerless grinding, we can usually reduce your coolant consumption by about 60%.

Tool grinding

Tool grinding refers to machining tasks that are necessary for the production or overhaul of a tool. These tools are often made of very hard materials due to their areas of application. This makes grinding more difficult and processing temperatures rise, which is why an adequate cooling lubricant supply is essential. The complex component geometries, for example in the case of grooves of a thread cutter and the associated changing contact areas, place high demands on the cooling lubricant supply. Thanks to the nozzles that Grindaix adapts individually to your process, sufficient cooling lubricant reaches all relevant zones that are difficult to reach and at risk of grinding burn. At the same time, we reduce the consumption of cooling lubricant, thus saving you money.

Gear profile grinding

In gear profile grinding, internal gears can be ground which are machined gap by gap. Here, a sufficient cooling lubricant supply to the machining zones on both tooth flanks and on the tooth base is crucial. In addition, the cooling lubricant must be transported directly to the internal gears that are difficult to reach during gear profile grinding. Our coolant nozzles enable a precisely metered and targeted supply. The coolant supply and coolant exit speed, which have been customized by our experts, ensure that the grinding wheel is thoroughly saturated. The grinding wheel transports the coolant to the correct and hard-to-reach gaps where it is needed to prevent grinding burn.

Internal cylindrical grinding

Internal cylindrical grinding is a process used for machining internal surfaces such as bores. However, this process in particular presents special challenges for the coolant supply. The very limited space between the grinding wheel and the workpiece leaves very little room for the nozzles of the coolant supply. Even though an optimal coolant supply is essential, the coolant often does not reach the machining zone directly. Our nozzle experts develop robust yet delicate coolant nozzles for precisely such processes, which can be manufactured using both 3D printing and conventional methods. The slim design and the use of specially bent nozzle needles ensure a targeted and demand-oriented coolant supply.

We would be happy to optimize your grinding processes with an optimal cooling lubricant supply and coolant nozzle!

Improve your process with our coolant nozzle!

Equipment for Grindaix coolant nozzles

The efficiency and durability of our needle nozzle for the supply of cooling lubricant can be increased with the right equipment. We offer the matching accessories!

Our coolant protectors, for example, can provide almost all nozzle geometries with wear protection. It thus serves as a wear protection plate, air baffle and stabilizer. Other equipment includes our cooling lubricant pressure gauges, or pressure sensors, as well as our coolant display and coolant pointer, for better alignment and display of your cooling lubricant data. Quick-change systems are used to quickly and easily exchange different nozzle variants and gFlex lengths..