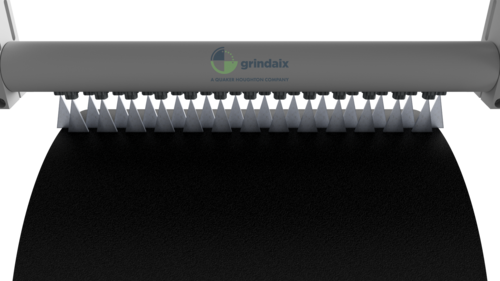

Grindaix nozzles for cleaning

- Reliable removal of chip residues

- Flushing of the grinding wheel pores

- Fresh lubricoolant is pressed into the grinding wheel pores at high pressure

- Improved grinding results

- Extended service life of the grinding wheels

- Easy assembly

- Available for all grinding wheels

During grinding, material removal leads to loading of the grinding wheel surface. The pore spaces of the grinding wheel become clogged with machining residues, such as chips, and can no longer take up any lubricoolant. Besides this, the residues in the grinding wheel rim have a negative impact on the surface quality. Influencing factors are the process-related chip formation geometry and the material to be machined. If the level of loading on the grinding wheel surface is too high, the machining zone cannot be provided with sufficient lubricoolant. Combined with the considerable friction that is generated, this leads to grinding burn and surface defects. Tool life is likewise negatively affected, as any loading chips on the grinding wheel which have not been removed by means of flushing must be eliminated through dressing operations.

The use of special high-pressure cleaning nozzles from Grindaix for removing residues from the grinding wheel pores brings many benefits:

+Reduction of grinding burn risk

+Reduction of tool wear and increase in tool life

+Improved lubricoolant supply by saturating the flushed pores

+Increase in productivity

+Improvement in the surface quality of ground parts

Although at 20 bar, the operating pressure of Grindaix cleaning nozzles is still high – and this is necessary for achieving an optimum cleaning result – the nozzles only consume low volumes of lubricoolant.

When cleaning grinding wheels, the orientation of the cleaning nozzles is also important. There are many opinions when it comes to deciding whether to spray in or counter to the direction in which the grinding wheel is rotating, or else vertically onto the abrasive layer. Then there is the issue of whether to take one row of cleaning nozzles or several.

As an experienced engineering service provider, we can provide you with expert advice when it comes to selecting the right cleaning nozzle and the correct positioning thereof as well as when setting the volume flow and exit speed – especially customized to your grinding process and your grinding wheel specification.

Clean your tools in an optimum way with Grindaix nozzles and achieve higher productivity!

- Einsatz von Hochdruckdüsen

- hohe KSS-Austrittsgeschwindigkeit

- gezielte KSS-Zufuhr

- Reduktion Werkzeugverschleiß

- Erhöhung der Produktivität

- einfache Montage

| Name | Type | Size | Download |

|---|---|---|---|

| Grindaix - Grinding wheel cleaning 2024 | 744 KB | download | |

| Grindaix - Questionnaire needle nozzle design 2024 | 641 KB | download |

Product inquiry

We would be happy to provide you with more detailed information on your desired topic. Simply send a non-binding inquiry to info@grindaix.de, and we will get back to you as soon as possible.

Examples of our cleaning nozzles in use

The Grindaix cleaning nozzles are individually adapted to the grinding processes. For this reason, the cleaning nozzle can be used for a variety of grinding processes and thus reliably remove chip residues on grinding processes from surface grinding to external cylindrical grinding.

Advantages of the cleaning nozzle in every grinding process:

- Cleaning the grinding wheel pores

- Flooding the free pores with coolant

- Increases the service life of the grinding wheels

- Quick and easy installation

- Removal of chip residues

- Reliably reduces grinding burn

- Achieving optimum cleaning results

Surface grinding

Surface grinding is used to machine flat surfaces and smooth the surface. However, the contact area between the grinding wheel and the workpiece is very large, which increases the risk of grinding burn if the cooling lubricant supply is incorrect. Above all, it can be difficult to transport the coolant to the contact zone if there is little clearance in the grinding machine and up to the contact zone. The cleaning nozzles from Grindaix GmbH help to ensure a targeted lubricoolant supply to the contact zone. The pores of the grinding wheel are rinsed free and filled with fresh coolant. Chip residues in the machine are also removed.

Gear profile grinding

During gear profile grinding, internal gears are ground, which are machined gap by gap. Sufficient lubricoolant supply to the machining zones is crucial. Furthermore, the cooling lubricant must be transported to the hard-to-reach internal gears during gear profile grinding, which presents a further challenge. The Grindaix cleaning nozzles enable an adequate supply of cooling lubricant. The grinding wheel pores are effectively cleaned and saturated with coolant so that it is transported to the internal teeth to prevent grinding burn.

External cylindrical grinding

External cylindrical grinding is used for hard-fine machining of cylindrical, i.e. rounded, external surfaces. A small installation space in the grinding machine for nozzle positioning and a targeted lubricoolant supply to the machining zone is often problematic. In such cases, the machining zone can be cooled well using the grinding wheel pores. The cleaning nozzle from Grindaix GmbH uses coolant to flush out machining residues from the pores of the grinding wheel and refill them. This transports the cooling lubricant through the grinding wheel into the machining zone and can reduce the risk of grinding burns.

Does the cleaning in your grinding process also need to be optimized?

Make an inquiry today!

Equipment for the Grindaix cleaning nozzles

The right equipment is essential for increasing the productivity of the Grindaix cleaning nozzle. As it often seems difficult to find the right accessories for nozzles, we have developed equipment that meets all requirements and fits Grindaix nozzles perfectly! With the Coolant Protectors, it is possible to provide almost any nozzle geometry with protection. In addition to wear protection, this also serves as an air baffle and stabilizer. Our coolant pressure gauges, as well as the Coolant Display and the Coolant Pointer from Grindaix GmbH, have been specially developed for better and faster alignment and display of your coolant data. Finally, the quick-change systems are used to exchange different nozzle variants and gFlex lengths quickly and practically.