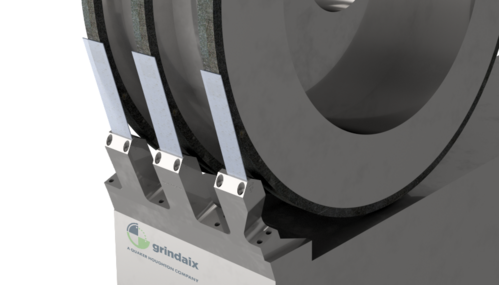

Grindaix extinguishing nozzles

- Avoid spark formation

- Bind dust and other dirt particles

- Reduce dirt on the machine tool

- Extend the service life of the machine tool

- Render operation of the machine tool easier

- Reduce the operators’ exposure to dust

Heavy spark formation often occurs during grinding processes.

A spark is a red-hot material particle which has taken up so much energy in the form of heat during machining that it begins to glow. Even sufficient cooling of the grinding zone is often not enough to prevent spark formation.

If heavy spark formation occurs in your machine tool, we recommend the use of extinguishing nozzles. These extinguish sparks reliably and also have a cooling effect on the part and the grinding wheel. By using an extinguishing nozzle, the material particles are bound in the lubricoolant. This is beneficial for several reasons:

+ Prevention of machine fires when using oil as a lubricoolant

+ Reduction in particle emissions (e.g. grinding dust) to the environment

+ Reduction in dirt and wear on the machine tool

+ Reduction in the machine operators’ exposure to particles

+ Particles collect centrally in the lubricoolant filtration system

Which pressure, which spray direction and which type of spray jet may be used to extinguish flying sparks in the most efficient way? We provide you with the answers.

We can produce a suitable extinguishing nozzle for your machine tool, customized to your grinding wheel and machine geometry in the form of a slotted nozzle. Grindaix extinguishing nozzles achieve the desired extinguishing effect even with low volumes of lubricoolant thanks to accurate orientation onto the spark jet. Upon request, we can equip your extinguishing nozzle with a coating to protect it from the highly abrasive effect of the spark jet and thus to increase its service life.

Our nozzle specialists look forward to receiving your inquiry!

- avoids flying sparks behind the machine site

- low lubricoolant consumption

- low space requirement

| Name | Type | Size | Download |

|---|---|---|---|

| Grindaix - Questionnaire needle nozzle design 2024 | 641 KB | download |

Product inquiry

We would be happy to provide you with more detailed information on your desired topic. Simply send a non-binding inquiry to info@grindaix.de, and we will get back to you as soon as possible.

Our extinguishing nozzles in use - examples

Grindaix extinguishing nozzles are individually adapted to the grinding processes and space available in the machines. Due to the small space requirement of the extinguishing nozzles, one can be installed in almost every grinding process. This means that flying sparks or machine fires can be effectively avoided and the component and grinding wheel can be cooled at the same time. This can be done for grinding processes such as surface grinding through to camshaft grinding.

Advantages of extinguishing nozzles for grinding processes:

- Avoids flying sparks behind the cutting point

- Low space requirement

- Low coolant consumption

- Binds dust and dirt

- Prevention of machine fires

- Reduction of particulate emissions

- Cools component and grinding wheel

Surface grinding

Surface grinding is the grinding of flat and often large surfaces. These surfaces are to be smoothed. However, the long contact length between the component being processed and the grinding wheel is problematic and leads to very high processing temperatures.

In such cases, it is important to cool the machining zone and extinguish the flying sparks caused by high machining temperatures in order to prevent machine fires. This is where the extinguishing nozzle specially developed by the experts at Grindaix GmbH comes in. The extinguishing nozzle's precise supply of cooling lubricant covers the machining zone and extinguishes the sparks. At the same time, the component and grinding wheel are effectively cooled.

Camshaft grinding

Camshaft grinding is a type of cylindrical grinding, whereby various problems can occur during the grinding process. On the one hand, engagement conditions change, which also results in a change in the position of the grinding points. Furthermore, a spark jet is created just below the machining zone, which must be extinguished, as high temperatures can lead to risks. This creates risks such as grinding burns or machine fires! The Grindaix extinguishing nozzle is designed both to extinguish the spark jet efficiently and to cool the machining zone. This means that grinding fires or machine fires can be prevented, but the change in position of the grinding points can also be taken into account.

Would you like to reduce flying sparks in your process?

Make an inquiry today!

Equipment for the Grindaix extinguishing nozzles

The Grindaix extinguishing nozzles require suitable equipment (accessories) to effectively increase productivity and longevity. However, it is often more challenging to collect this equipment than initially thought. For this reason, we have developed equipment that meets all requirements and is precisely tailored to the Grindaix nozzles!

With the Coolant Protectors from Grindaix GmbH, almost any nozzle geometry can be provided with protection. Aspects such as wear protection, air dissipation and stabilization can be covered with the Coolant Protectors. The coolant pressure measuring devices, the Coolant Display or the Coolant Pointer, have also been developed for special tasks. They are designed to make the alignment and display of your coolant data better and faster. The quick-change systems, on the other hand, make it easier to exchange different nozzle variants and gFlex lengths quickly and practically.